MS365 wood tenoning machine for floor making

| Condition:New | Application:woodworking,milling wood edge or wood floor making | Automatic Grade:Manual | Motor Speed:9700/7500/5200r/min |

| Max Processing Thickness:5mm | Place of Origin:Guangdong China (Mainland) | Brand Name:Xinnianhua or Sunnywei | Model Number:MS365 |

| Voltage:380v 50hz 3ph | Power(W):4 or 5.5kw | Dimension(L*W*H):2800*750*1200mm | Certification:CQC,ISO 9001:2008 QS-9000 |

| Color:White and green, other color need customize | Quality:must conform to export standard | MOQ:can be one set for trial order | Payment:by t/t |

| Lead time:20days after receiving the deposite | Packing:pearl wool or plywood case | Type:Mortise device,wood tenoning machine |

MS365 wood tenoning machine for floor making

USE OF THE MACHINE

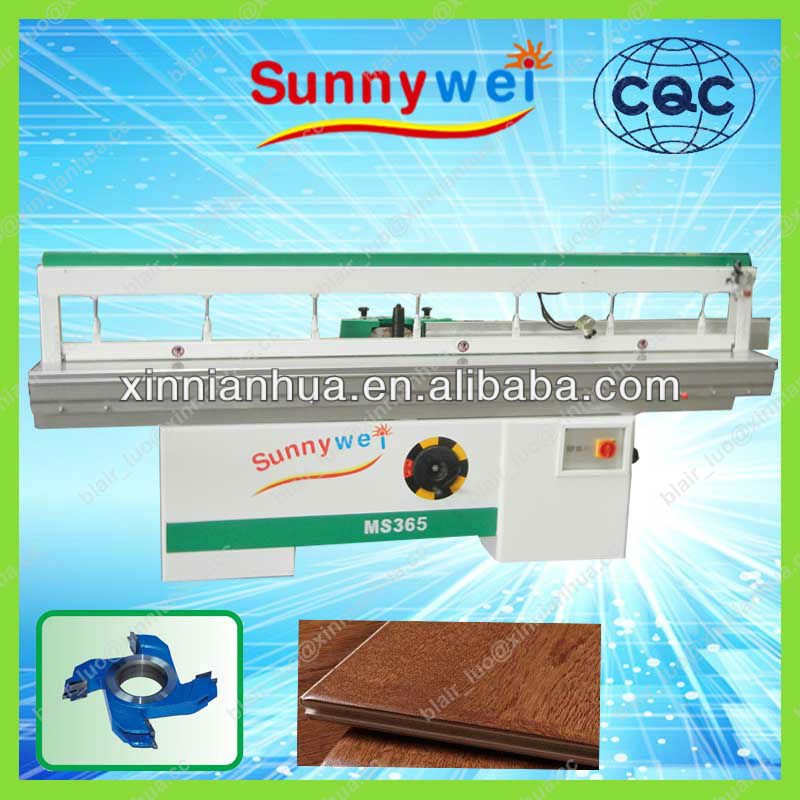

This machine is maily used for milling concave-convex tenon slot, long slot finishing of the wooden door ,wood flooring processing, but also can plane the curved and straight edge,bevel edge,and making variety of wooden lines with the mold.

It is suitable for the woodworking furniture industry.

MAIN SPECIFICAITON AND TECHNOLOGY PARAMETER

| MODEL | MS365 |

| Slide worktable max distance | 3000mm |

| Max processing length | 2600mm |

| Max working width | 5mm |

| Max working depth | 5mm |

| Dia of cutter spindle | Φ35mm |

| Rotary speed of cutter spindle | 9700/7500/5200r/min |

| Main spindle lifting height | 100mm |

| Install power | 4kw(5.5HP)/380V 50Hz |

| Consumption of pressure | 0.6mpa |

| Weight of machine | 560kg |

| Overall dimensions(L×W×H) | 2800×750×1200mm |

Advantage:

1.mainly use for milling concave-convex tenon slot long slot finishing

2.Pneumatic pressing materials function, high precision, decrease hard work, and high efficiency

3.Also can be used for planing surface finishing curved and straight edge

4.Body made of excellent steel plate, with enough rigid

5.Main spindle through refine grinding processing

6.Installed protect cover on main spindle cutter and aluminium baffle

7.Adopt steel ball double side structure with high precision, the error of straightness on whole distanc e of travel is less than 0.15mm.

8. Quality electric part with Schneider Brand

9. Motor add over load protection

Pictures:

Thank you for your attention!

| Packaging Detail:wooden case or pearl wool |

| Delivery Detail:20-30days |