wood chips rotary dryer machine for wood sawdust drying equipment

| Condition:New | Type:Flash Drying Equipment | Place of Origin:Henan China (Mainland) | Brand Name:Allance |

| Model Number:ALC6-WD5 | Voltage:380V | Power(W):12.5kw | Warranty:one year |

| After-sales Service Provided:Engineers available to service machinery overseas | capacity:1000-2000kg/h | moisture:35%-50% | maximum feed size:5mm |

| cubic oven:1.42*1.42*1.41m | round oven:1.23*1.24*1.73m | pipe:2.45*1.72*1.91m | Name:wood chip dryer |

| Usage:wood chip dryer for chips drying | Product Type:Wood chips /sawdust dryer |

wood chips rotary dryer machine for wood sawdust drying equipment

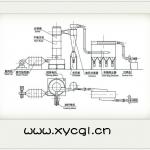

Principle

Our wood chip dryer adopt hot air jet device for automatic suction,hot airflow with high speed,which can get the full air mixing materials,good drying effect . 40% moisture of the material can be dryed until get the standard that can be used by system stick machine (8%-12%), the processing of drying only need one time.

Advantage about wood chips dryer

Our wood chip dryernot only reduces the labor intensity but also can reuse the fuel gas from the carbonization furnace . During the carbonization process methane and carbon monoxide and other combustible gases produced during the carbonization process can be processed by the filters as light as the gas dryer for comprehensive budget,the annual fuel cost can be saved ten of thousands .

Structure for wood chips dryer

Oven parts

1.Within the drum, two layers of insulation.The drum has three spiral pieces,which can dry materials by moving around until evenly heated frying.

2.It also adoped snake-like tube and using of the negative pressure ventilation fan to dry the material in the pumping pass to the spiral separation to get the drying effect.

3.Two oven,one is cubic oven,another is round oven,the unite using can accelerate the drying process.

4.11kw is fan power ,0.75kw is air-lock valve,the other is dial feeder.

Main parameter

| Model | Power(kw) | Capacity (kg/h) | Moisture Content | Dimension(m) |

| ALC6-WD1 | 4kw | 300-400 | 12%-35% 2-3times | 2.44*1.23*1.9 |

ALC6-WD2 | 7.5+1.5kw | 400-500 | 12%-35% | Cubic oven: 1.4*1.32*1.4 |

| Pipe:2.44*1.72*1.87 | ||||

ALC6-WD3 | 11kw | 800-1000 | 12%-35% | Cubic oven:1.45*1.42*1.41 |

| Pipe:2.45*1.72*1.91 | ||||

ALC6-WD4 | 4+1.5+1.5kw | 150-200 | 35%-50% | Cubic oven: 2.44*1.22*2.15 |

| Round oven: 1.25*1.25*1.75 | ||||

ALC6-WD5 | 11+0.75+0.75kw | 1000-1200 | 35%-50% | Round oven:1.23*1.24*1.73 |

| Cubic oven:1.42*1.42*1.41 | ||||

| Pipe:2.45*1.72*1.91 | ||||

ALC6-WD6 | 15+1.5+0.75kw | 1100-1300 | 35%-50% | Round oven:1.23*1.24*1.73 |

| Cubic oven:1.42*1.42*1.41 | ||||

| Pipe;2.45*1.72*1.91 |

Wood chips/wood sawdust

wood chip dryer

| Packaging Detail:standard wooden case |

| Delivery Detail:7-10 days after recieve the deposit |