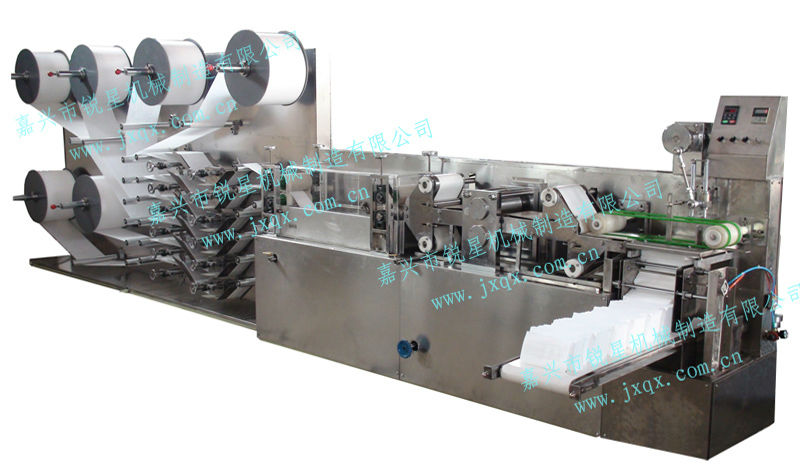

wet wipes folding equipment

| Condition:New | Place of Origin:Zhejiang China (Mainland) | Brand Name:Qx wet wipes machine | Model Number:QX-6F |

| Voltage:380V | Power(W):50Hz | Dimension(L*W*H):7800mm*1200mm*2000mm | Weight:3500kg |

| Certification:wet wipes making machine | Warranty:wet wipes machine warranty period 3years | After-sales Service Provided:Engineers available to service machinery overseas | wet wipes machine:QX-6F |

| wet wipes machine speed:about2000-2500 | wet wipes machine raw materail:high-quality steel and stainless steel | wet wipes production line:with a packaging machine | wet wipes machine weight:about 3500kg |

| wet wipes production machine dimension:7800mm*1200mm*2000mm | can be customized:wet wipes machine | high speed wet wipes machine:high efficiency | Rated voltage of machine:380V |

| wet tissue production line:many kind of wet wipes making machine can be customized |

It equips with multifunctional folding system which can fold“N”,“C”,“double Z”; the number of feeding rolls and the folding device can be tailor made as requirements. The PLC programming system can be added on the machine with computer touch screen and the servo driven system to control the production. It can process: spun-lace nonwoven, spun-bonded nonwoven, and the needle punch fabrics etc. The raw materials are by folding–liquid-adding- cutting- counting - stacking–outputting- finished products

COMPANY OVERVIEW

As a company based on technology innovation, honest and trustworthy, be vigilant in peace time. Our company invested heavily in new equipment R & D and existing equipment improving and have achieved many government commend and reward.QZ3-1200 multifunctional automatic non-woven bag making machine is developed in such enterprise culture. QX3-1200 multifunctional automatic nonwoven bag making machine improves drive,edgefold,ultrasonic bonding. Add the cylinder delay pressurization system in original position of hot-press system and it can be cold pressing or hot pressing according to client’s request. The device can produce flat nonwoven bag ,vest nonwoven bag ,three-dimensional nonwoven bag etc.QX3-1200 is popular in home and foreign ,it sells to Jiaxing city ,Wenzhou city ,Shandong province ,Hebei province ,Shanghai city ,Guangdong province ,Sichuan province and export many countries. The product produced by QX3-1200 is received the WAL-MART supermarket recognition etc. It’s the biggest affirmation for us. It less cost about 0.8 yuan than manpower.Low investment, high yield, profit space is large, wide range of uses ( internal and external packaging, shopping bags can be used ), market competition advantages.QX3-1200 multifuntional automatic nonwoven bag making machine has adopted the guide folding system, ultrasonic bonding and system, synchronous tension control system, cutting system, computer control system, the appearance of timber and other technical indicators leading international. Similar products can not be comparable with our factory.

SPECIFICATIONS

Exclusive domestic research and development, the device per minute production in 1500-2000pcs, compared to the production of more efficient than the first generation QX-5F, better use the recommended models, has been successfully applied for the patent, without thethe company allowed the use of the company's picture and video promotion, the company will pursue its legal responsibility.

- Processability of raw material: spunlace nonwoven fabric, hot air cloth, rolled cloth, acupuncture cloth.

- Machine with plant design multifunction the profiled folding system, folding N, C, Double Z and other specifications can be adjusted within a certain range, and gear CVT control the length of the product.

- The machine is equipped with 6 foot raw material feeding system, starting with the raw materials traction - automatic folding - automatic liquid - automatically roll off - automatic stacking - about dislocation count - automatically output products, the whole line is fully automatic complete.

- Dimensional accuracy of the machine with 6 tension controller to adjust the tension of the finished product to guarantee folding.

- The machine is equipped with a complete set of automatic liquid automatically roll off the cutting device and product output system.

- Machine the entire delivery system used in all imported conveyor transport, solid, durable, non-polluting.

- The machine adopts imported converter control operation, was equipped with a PLC program and a color touch screen, cabling specifications, simple, safe and easy to operate.

- Machines involved in product parts are madeof stainless steel, bearing domestic quality 45 # steel material, the use of high-quality bearings.

- Machine rack adopt international channel welded surface for anti-rust paint treatment, the exact size of the welded frame the bracket appropriate reinforcement, pulleys, gears and transmission parts,center poison accurate to ensure smooth operation of the machine.

- Standard parts used in all domestic quality 45 # steel screws and Allen screws, stainless steel screws impact on the finished product easy.Machine all plating finish, anti-rust properties.The device was equipped with PLC programming procedures, the servo electrical, color touch screen control joint production, complete automatic stacking and output products cropped, greatly improve work efficiency.

| wet wipes machine model | QX-6F |

| wet wipes making machine producing speed | 1500-2000pcs/min |

| wet wipes machine rated voltage | 380V |

| wet wipes machine rated frequency | 50Hz |

| wet wipes machine dimension(L*W*H) | 7800*1200*2000 |

| wet wipes machine weight | about 3500kg |

| Packaging Detail:wet wipes making machine packaged in wooden case |

| Delivery Detail:30days |