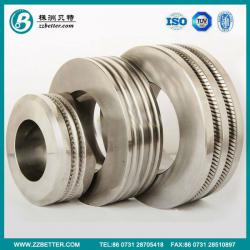

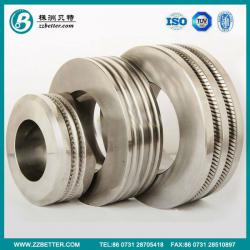

tungsten carbide finishing mill roll for ribbed wire/carbide rolls/rolling mill roll/carbide roller

| Condition:New | Type:Cold Rolling Mill,Hot Rolling Mill | Place of Origin:Hunan China (Mainland) | Brand Name:ZZBT |

| Model Number:Various type | Voltage:220v | Power(W):standard | Dimension(L*W*H):As customer's requirement |

| Weight:different type have different weight | Certification:ISO,ISO9001:2000 Certificate | Warranty:6 months | After-sales Service Provided:Overseas service center available |

| Name:carbide finishing mill roll/carbide roll/rolling mill roll/roller | Material:Tungsten carbide | Service:OEM | Content:Wc+Co |

| Trial order:Acceptable | Feedback:within 24 hours | Color:metallochrome |

tungsten carbide finishing mill roll for ribbed wire/carbide rolls/rolling mill roll/carbide roller

tungsten carbide finishing mill roll for ribbed wire/carbide rolls/rolling mill roll/carbide roller iswidely used as seal faces with resistant-wearing, high fractural strength, high thermalconductivity, small heat expansion co-efficient. It is the best material to resist heat and fracture in all hard face materials.

Many size available:

| Application requirements of dimensional tungsten carbide roll | |||||

| 1. Any striking on and collision with roll rings is strictly prohibited. | |||||

| 2. When installing the whole assembly of roll rings, the clearance of the bearings in relation to the casings should be on | |||||

| the tighter side . | |||||

| 3. The precision of rotation of the whole assembly ( circular runout and end runout ) should be kept within ±0.05mm. | |||||

| 4. The fitting -in of the whole assembly and the roll rings shall be a transitional fitting -in and fastened. | |||||

| 5. The roll rings should not be cooled by water or oil water emulsion. | |||||

| 6. The joints of the pipes in the internal cooling system should not be leaky and it is advisable that no cooling is applied. | |||||

Our tungsten carbide finishing mill roll for ribbed wire/carbide rolls/rolling mill roll/carbide roller have good performance in the precision rolling mill.

We can peoduce the special size tungsten carbide finishing mill roll for ribbed wire/carbide rolls/rolling mill roll/carbide roller as customer's requirement.

If you use our tungsten carbide finishing mill roll for ribbed wire/carbide rolls/rolling mill roll/carbide roller ,your steel wire will be very popular in your market.

Carton case or wooden case and inner plastic bag. Also we can pack as customer's requirement.

l Rods & Endmill

l Stripes & Plates

l Cutting tools

I Ring & Rollers

I Blade & Disc Cutter

I Turning Tool, Insert & Tips

l Solutions for Polyolefins Industry

l Application in Coating Industry

l Wear parts of Concrete Pump

l Products for mining industry

l Other Customized Items

l Tungsten Heavy Alloy

I Non-standard Mechanical Parts

| Packaging Detail:Packed in carton box and inner plastic bag. |

| Delivery Detail:Within 10-30 days upon confirm the order. |