Thickener with central rack transmission

| Type:Mining Thickener | Condition:New | Application:mining,Ore | Motor Type:AC Motor |

| Power(W):1.1KW-7.5KW | Place of Origin:CN,China (Mainland) | Brand Name:JINPENG | Model Number:NZS |

| After-sales Service Provided:Engineers available to service machinery overseas |

Yantai Jinpeng Mining Machinery CO., LTD

Add:No.11, Fuzhou Road, development District, Yantai, Shandong Province

Tel: 0535-3975297 Fax: 0535-3975297

Application

This machine is a singledeck high performance thickener used in the process of performance

thickener used in the process of wet concentrate dehydration, usually is used in the first phase

of the dehydration process. The products usually can get concentration with water content 30-60%, the equipment usually is located between the concentration and filtering devices, sometimes can also be used as dehydration unit.

Equipped with deaerating tank to prevent solid particles from adhering to the bubbles, and to subside like "parachute '. The feed tube is located below the liquid surface to avoid air blending with the pulp, and jagged overflow weir reducing the chance of uneven suction phenomenon.

Characteristics

(1) Its flocculant enlarges the size of solid particles and thus increases the speed of sedimentation;

(2) Its oblique plate shortens the sedimentation distance of ore grains and increases the area of sedimentation;

(3) Flocculate, filer and compress the sludge sedimentary thick-phase layer; and improve the treatment capacity;

(4) Have the complete automatic control facilities.

Main work characteristics

The flocculant of a certain amount in ore pulp aggregates the ore grains into flocculi, accelerates the sedimentation, and thus improve the concentration efficiency.

The concentrator (highefficiency concentrator) is widely used to treat the ore pulp, waste water and waste slag in various fields (e.g. metallurgy, mine, coal, chemicals, building materials and environmental protection). It plays a significant role in improving the utilization rate of backwater, increasing the transmission concentration of underflow, and protecting the environment.

Types

Central driving concentrator, peripheral driving concentrator, high-efficiency concentrator, sludge concentrator, intermittent concentrator, and vertical/radial-flow continuous concentrator.

Description (high-efficiency)

It is generally composed of concentrating pool, pallet rack, driving device, pallet rack lifting device, feeding device, discharge device and signal safety device.

In the bottom center of the tank located a discharge bucket, around the pond there is a circular overflow tank. A vertical axis is situated in the tank’s center, on the axis’ end fixed a cross rake, under which is a scraper. The angle between the rake and the water level is 8 ° ~15 °. Vertical axis is driven by the motor on the truss. When the vertical axis rotating, the pulp along the feed chute on the truss entering to tank center, at the same time flowing around the tank. Solid particles in the pulp gradually settle down to the tank’s bottom, and scrapped by the scraper under the rake into the discharge bucket and released though the sand pump. The clarified water above flows from the circular overflow tank. If the thickener overloaded may cause the discharge bucket block or rake frame distortion. To prevent this phenomenon, it is equipped with signals safety device and rake lifting device.

Installment and Usage:

1. Installment:

Thickener installed on the site as a whole.

Keep the spindle, rake concentric with the discharge basket.

Note: The thickener can not run reversely.

2. Trial Run

A. Noload trial: the run time should be 8 hours, the temperature of motor and transmission parts should not exceed 50 °C.

B. Load trial: testing time is 8 hours, filled with liquid water.

3. Running

A.Check whether the discharge pipe and the transmission mechanism works normally, and must be confirmed there is no foreign matter in the pond before start the equipment.

B.Pay attention to the equipment’s load, the overflow and concentrate’s concentration.

C.One of the major fault of the equipment is the discharge bucket’s block, many reasons maycause that, such as coarsegrained particles, wood chips, rags falling into, the block is more

likely to occur when the sand pump not working. When the block happens, must shut down the gate on the concentrate pump and then feed the highpressure water into the discharge bucket to solve the block problem. If foreign matters falling into the thickener, should discharge the pulp completely then clean the tank.

D. Fasten the bolts timely after the operation.

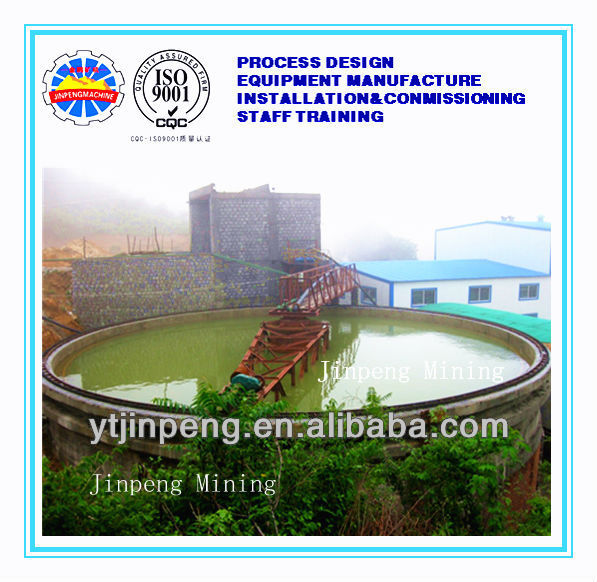

Onsite Application

Yantai Jinpeng Mining Machinery CO., LTD

Add:No.11, Fuzhou Road, development District, Yantai, Shandong Province

Tel: 0535-3975297Fax: 0535-3975297

| Packaging Detail:Container, in bulk or others as the buyer's requirment |

| Delivery Detail:30-60days |