The high oil output scrap tyre recycling pyrolisis oil plant for sale

| Condition:New | Type:Tire Machine | Tire Machine Type:Tire Recycling Machine | Place of Origin:HEN,Henan,China China (Mainland) |

| Brand Name:LEABON | Model Number:YL-18,YL-18 recycling pyrolisis oil plant | Voltage:220/380V,220/380v/50HZ | Power(W):12KW,12 |

| Dimension(L*W*H):5000*2200mm | Weight:5T,5 t | Certification:CE | Warranty:1 year |

| After-sales Service Provided:Engineers available to service machinery overseas | Brand:LEABON recycling pyrolisis oil plant | Power Consumption:low | Size:6000*2200mm |

| Capacity:8t recycling pyrolisis oil plant |

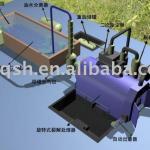

Recycling pyrolisis oil plant

preface:

Waste or Treasure?

Waste tire, waste plastic, waste rubber, waste oil etc. are increasing every moment.At the same time, oil resources

are decreasing every single day.How to deal with these problemsWe use green

technology recycling waste to oil resources.We are specialized in manufacturing pyrolysis machine for recycling

waste tires, waste plastic, waste rubber etc.

1. Brifeintroduction

A. The advanced equipment can refine fuel-oil by making use of waste-tire, rubber, plastics and oil mud continuously.

B. The complete set equipment is the most advanced equipment in international and domestic which is used to dispose waste tires and waste plastics.

C. It adopted the sealed pyrolysis process and has the features of making waste plastic and rubber into treasures without secondary pollution. Putting raw materials into rotating cracking vessel, then closing the feeding door(according to the production capacity to put materials and the operation regulations to operate),

2.Main features

Safety:

1. With an auto welding machine for the reactor, it can not only greatly improve working efficiency but also guarantee the quality of welding seam, thus avoid explosion caused by gas leak.

2. Professional heating treatment and x-ray detection chamber are especially for welding.

3. Vacuum system will prevent oil gas from going back to reactor and causing accident.

4. Professional thermometer, pressure gauge and safety valve.

5. It is dangerous to burn exhaust gas(C1 to C4) without any safety measures. In our process, it is transferred first through the safety device and a safety burning air muzzle. Before burning, we should ensure the safety of production.

Environment friendly:

1. Well water de-dusting system can avoid black smoke.

2. The exhaust gas will be recycled for heating reactor, no gas pollution

3.Every junction of the reactor is in good sealing situation with professional sealing material.

3.Raw Materials and final product

4.Process description

Feed the scrap tyres directly into the revolving-normal pressure split processor, catalyze, and heated, distillate oil vapor, transfer the oil vapor. Then through condenser, the liquefiable phase condensed to tyre oil. The unliquefiable ones come through gas system, and were burnt in the bottom of the processor. The black carbon after cooling will be discharged automatically through the outlet

5. Technical Parameters of waste tyres pyrolysis equipment

Reactor

1. The gear is seperated from reactor, instead of welding on reactor. So it will not be destroyed by heating.

2. The reactor is supported in a centre line by rollers. It will remain stable while running.

3. Auto-welding, both inside and outside.

4. Made by special boiler plate Q345R. Security and long service life.

5. Made by rock wool insulation board. Save fuel and ensure heating effect.

| Items | Contents | ||||

| 1 | Equipment type | YL-15 | YL-18 | YL-20 | |

| 2 | Raw material | Waste tires/plastic/rubber | |||

| 3 | Structural form | Horizontal rotation | |||

| 4 | 24-hour Capacity | 5 tons | 8 ton | 10 ton | |

| 5 | Oil yield | 2.25-2.5 | 3.2~3.6 ton | 4.5~5 ton | |

| 6 | Operating pressure | Normal | |||

| 7 | Material of reactor | Q345R | |||

| 8 | Thickness of reactor | 14mm | |||

| 9 | Rotate speed of reactor | 0.4turn/minute | |||

| 10 | Total power | 12KW | |||

| 11 | Mode of cooling | Water cooling | |||

| 12 | Kind of transmission | Internal gear drive | |||

| 13 | Noise dB(A) | ≤85 | |||

| 14 | Size of Reactor(D×L) | 4500×2200 | 5000×2200 | 6000×2200 | |

| 15 | Working form | Intermittent operation | |||

| 16 | Delivery time | 20days | |||

| 17 | Weight | 4.6T | 5T | 5.5T | |

6. The products getting after pyrolysis operation are as follows:

1. Crude oil: 40%~ 45 %( Because the oil production depends on the quality of the tyre and usually it's between 40%~45%)

2. Steel wire: 13%

3. Carbon black: 37% (can be used to make briquette)

4. Waste water and steam: 5%~10%

7.Profit analysis(take the YL-18 as an example)

1.8t of waste tyres (Crude oil: 45 %): 8t×1,300 Yuan/t=10,400 Yuan

2. 400 kg of coal: 320 Yuan

3.The electricity and water: 200 Yuan

4.Catalyst and chemicals: 20 Yuan

5.Workers' wages: 200 Yuan/day (4 people)

6.Environmental protection projects:Duty free

7. Total: 11140 Yuan

Fuel oil: 3.6t× 4,500 Yuan/t=2,400 Yuan

Steel wire: 8t×10%=0.8t×3,000 Yuan/t=2,400 Yuan

Carbonblack: 8t×40%=3.2t ×300yuan/t=960

Daily profits: 16,200 Yuan+2,400 Yuan+960 Yuan-11,140=8,420 Yuan

Monthly profits: 8,420×25 days=210.5 thousand Yuan(Suppose that a month is 25 days)

Yearly profits:210.5 thousand×10=2.105 million !(Suppose that one year is 10 months)

8.Safety product

Our machine equipped with anti-clogging device, pressure gauges, alarming System, safety valves, negative pressure device(vacuum device), oil-water Separator. Usually our machine is working under normal or negative pressure. In case of congestion, cause pressure, alarming system will ring, if no response from workers, safety valve could release pressure automatically. Negative pressure device could make sure our machine working under negative pressure, more safety. Oil-water separator could avoid oil gas go back to reactor, cause explosion

9.Photos of Factory

| Packaging Detail:Standard packing |

| Delivery Detail:within 20 days after receipt of deposit |