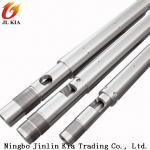

Single plastic machine screw barrel for PE film extruder machine

| Place of Origin:Zhejiang China (Mainland) | Brand Name:WX | Model Number:WX-002 | heat treatment:Nitriding |

| Hardness After Tempering:HB260-290 | Nitriding Hardness:HV950-1020 | Nitriding Case Depth:0.55-0.85mm | Nitriding Brittleness:Less than Grade 2 |

| Surface Roughness:Ra 0.4 | Screw Straightness:0.015mm | Chrome-plating depth:0.02-0.15mm | Alloy hardness:HRC59-65 |

| Alloy Depth:2.0-3.0mm |

Single plastic machine screw barrel for PE film extruder machine

| Diameter | Φ15mm-350mm | Designing | Screw structure and compression ratio can be designed according to different products & different output re quirement. |

| Materials | 38CrMoAlA (JIS SACM645) SKD61 | Application | Suit for HDPE , LDPE, LLDPE,PVC,PP ,glass fiber ,PPS ,PPA and other special plastic recycling . |

| Nitride Case Depth | 0.55mm-0.85mm | Technology | 1)Longer time Gas Nitriding treatment 2Special corrosion & abrasion alloy (bimetallic) 3)Tungsten carbide 4)Cobalt base alloy 5)Stainless steel 6)GH113 nickel based alloy |

| Nitride Hardness | 950-1020HV | Packing | Wrapped up by film in wooden case |

| Nitride Brittleness | ≤Grade Two | Payment Term | T/T , L/C , WESTERN UNION |

| Surface Roughness | Ra0.4um | Delivery Term | 25 working days |

| Screw Straightness | 0.015mm | Port Departure | Shanghai/Ningbo |

| Alloy Hardness | HRC59-65 | Min. Order | 1 set |

| Alloy Depth | 0.55mm-0.85mm | Guarantee | Common Nitrided:2-3years Bimetallic: much longer lifetime |

| Five-Star ADVANTAGES | 1.Advanced nitriding technology: we have our own nitriding equipment. 2.Duplex metal spraying technology for high corrosion and abrasion resistance 3.We use special alloy powder being sprayed and welded on the screw's ridge,and use different alloy and welding methods for the screw of different functions. 4.Fast and on time delivery . 5.Longer lifetime for the screw barrel. 6.Excellent aftersales service | ||

Advantages of Single plastic machine screw barrel for PE film extruder machine:

- Advanced nitriding technology

- Duplex alloy spraying technology

- High corrosion&abrasion resistance to prolong lifetime of screw and barrel

- We use special alloy powders being sprayed and welded on the screw's ridge/flight,andusedifferent alloy and welding methods for the screw of different functions.

- For good plasticizing , it has many designs to meet customers' demand . Such as granual type , mutant type , wave type , barrier type , double screen typr ,shunt type , separation type , exhaust type and so on .

- We can design for you with high cost-effective .

ABOUT US:

Zhoushan Five-star Machinery Manufacturing CO., LTD is located in Jintang town of Zhoushan City.

The town, which is named as Screws And Barrels Town in China, has excellent geographical location. It is in the north of Ningbo, in the south of Shanghai. After more than 20 years development, our company has been a famous high-quality screws and barrels supplier and pioneer in China. “Five-star” brand is awarded as “China Famous Best-seller brand” for screw and barrel by China Brand and Marketing Strategy Promotion Committee.

Contact Us for Single plastic machine screw barrel for PE film extruder machine Quotation or Support:

To make you an accurate quote, we need your kindly support to provide drawings, quantity, material, heat treatment requirements, destination, etc.

1.Please send us meassage online now.

2.Please contact us by E-mail.

If you have any need, please feel free to contact me. Veronica is here!

| Packaging Detail:Wrapped up by film in wooden case |

| Delivery Detail:25 days after order confirmed |