Single grade Reverse osmosis system/bottle Drinking water production plan

| Condition:New | Type:RO | Medium Material:PP | Place of Origin:Guangdong China (Mainland) |

| Brand Name:ANGEL | Model Number:RO-1000 | Voltage:220V/380V | Power(W):2.75KW |

| Dimension(L*W*H):2300*560*1800MM | Weight:230KG | Certification:CE ISO | Warranty:12 months |

| After-sales Service Provided:Engineers available to service machinery overseas | Capacity of pure water::1000 L/H | RO membranes::ESPA 4040 | Multi-phases pump::CDL2-180/2.2 KW |

| Beforehand filter::300x1200 | PP sediment membranes filter::90x1000 | Booster pump::BLC70/0.75 KW | Active carbon filter::1 item |

| Quartz sand filter::1 item | Machine material::Food grade stainless steel 304 | Outlet water quality::Pure water, standard drinking water |

Single grade Reverse osmosis system/bottle Drinking water production plan

RO pure water apparatus adopts the advanced technology of super-low-pressure reverse osmosis to purify the portable water and running water.

With all kinds of beforehand filters, it can get rid of the unhealthy substances such as sand, grits, suspended substances, bacteria, virus, pesticide residue, heavy metallic ions, and also can get rid of the carcinogenic substances such as chloroform, fluorine.

It can be used as water treatment apparatus in the field of food, drink, chemical, pharmacy, semiconductor, electronics and so on.

Inlet water quality: conform to the hygienic standard of potable water (GB5749-2006) and conductivity :400us/cm

Outlet water quality: conform to the hygienic standard of potable water (GB17324-2005) content of chlorine residue in raw water :0.1mg/l

Full automatic with qualified components, FRP or SS pre filter tank, ultra filtration membrane auto, manual flush, manual wash by chemical agents, auto stop running under the condition of high water level (or high pressure), auto start running under the condition of low water level(or low pressure), multi stage pump is protected when no power supply, poor power, exceed large electrical current, short circuit or creepage

Quartz Sand Filter

Usage: Mainly used to remove the algae, suspended solids, colloid, etc

Active carbon filter

Usage: Mainly used to remove water odor, residual chlorine, chloride and heavy metals, reduce color and optimize water quality.

Sodium ion exchanger

usage:Mainly usedfor removing calcium and magnesium

Precision filter

Usage: Mainly used to remove water tiny impurities.

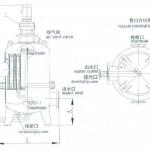

RO system

Usage: This device is used to remove the germs, the harmful inorganic ion, and organic ion; remove heavy metals and salt; rearrange water structure. It is the ideal equipment to make high standard pure drink water.

Single grade Reverse osmosis system/bottle Drinking water production plan

Filtration flow chart

Source water---Booster pump---Quartz sand filter---Active carbon filter---PP sediment filter---RO membrane---Filtration system

Procedure function

1.Concentration of hazardous or toxic substances in backwash and any waste effluent no greater than feed water.

2.Direct handling of hazardous or toxic substances

3.No special tools required for routine service supplied with system

4.Pump ON/OFF operating state controlled through communication interface

5.Fault reset provided through the communication interface

6.Total gallons processed calculated and available through the communication interface, but the cost extra

7.Differential pressure across each system stage available through the communication interface

8.System operating state / mode available through the communication interface

9.Backflow prevention valve in processed water outlet

10.Detect and report fault due to feed water: TDS > 1000 ppm; turbidity > 100 NTU, temperature 45 C; catastrophic leaks; conditions which indicate a possible failure to remove fecal coliforms to the level specified

Products catalog:

Angel Drinking Water Equipment Co., Ltd is located in Jiangmen City, Guangdong province, China, the most famous Hometown of Overseas Chinese. Our company always insists on the tenets “Improving water quality; Benefiting human; Developing ourselves; Devoting society”, and pursues the ideas “Survive in quality; Develop with innovation; Base on credibility; Benefit from management”. Because we also relies on research institutes and technical colleges to get support,we offer best and excellent products in this line. Up to now, our company has become one of the largest and earliest manufacturers in China specializing in making water treatment apparatus, bottling machines and correlative auxiliary equipments.

All staff warmly welcome new or old customers come for consultation. In order to make filling machinery achieved your ideal requirements, we will be making detailed project plan, to realize low cost, high efficiency and scientific process combination.

Automatic water purification plant/ drinking water processing project

Welcome to visit our factory.

Any inquiry please feel free to contact me directly.

Ms. Michelle

0086 15975016436

| Packaging Detail:1.Cover by PVC film + wooden case+ solid wood pallet; 2.Wooden case suitable for long distance ocean shipping. |

| Delivery Detail:In 25 days after receiving the deposit |