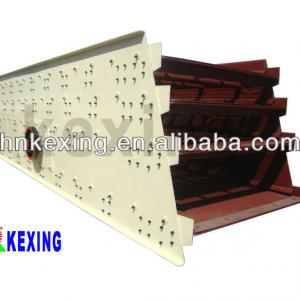

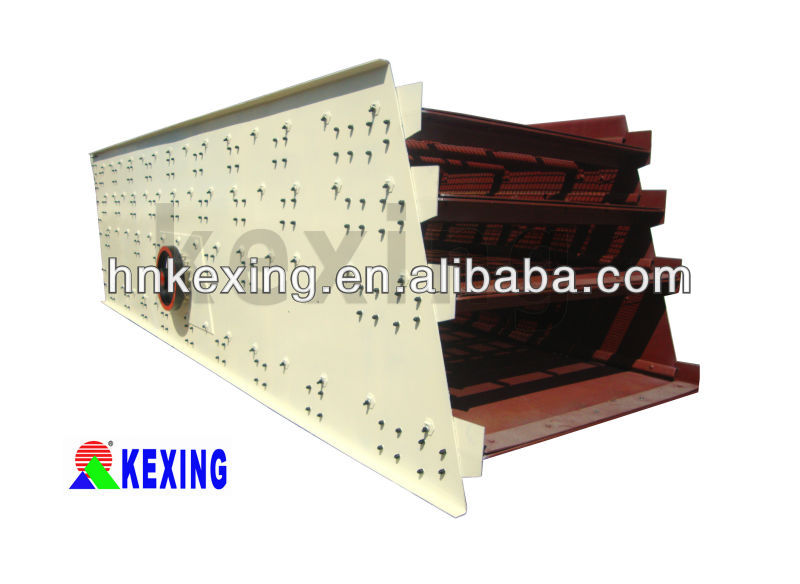

Sand vibrating screen Shaker sieve machine Separator

| Condition:New | Type:Circular | Application:Ore | Place of Origin:Henan China (Mainland) |

| Brand Name:Kexing | Model Number:multi-model | After-sales Service Provided:Engineers available to service machinery overseas | Application::mineral,cement,corhart,bauxite chomotte,etc |

| Colour::red, yellow, blue, ect | Certification::CE ISO9001:2000 |

Sand vibrating screen Shaker sieve machine Separator

Brief Introduction:

The Vibrating Screen (Vibratory Screen) is of many layers and high efficiency. The vibratory screen adopts the barrel type of eccentric shaft vibration exciter and eccentric block to adjust the swing. The screen is of the flowing characteristics, the screening line is long and specification of materials screened is various, and it is also of reliable structure, strong exciting force, high screening efficiency, low vibrating noise, long durability, convenient maintenance, safe operation, etc, and the vibratory screen is widely used for screening in wide range including mines, building material, transportation, energy sources, chemical industry, etc.

Sand vibrating screen Shaker sieve machine Separator

Advantages:

1. new structure ,advance technical data, high processing capacity and high screening efficiency

2.Circular Vibrating Screen adopts tube-type eccentric shaft vibration exciter and partial block of conditioning amplitude; easy operation and maintenance.

3. Circular Vibrating Screen with spring steel woven mesh or perforated metal sieve, long life, not easily plug holes.

4.Circular Vibrating Screen with rubber isolation springs, long life, low noise, and pass through resonance region easily.

Sand vibrating screen Shaker sieve machine Separator Usage and maintenance:

Vibrating screen should start wihtout the materials on the screen surface, and try to avoid start the mahcine with materials, screen machine should make sure to run smoothly before feeding material. Before halt, feeding materials should be first stopped and all the materials are discharged. In the working process, the operating situation must be checked regularly, once operate improperly or have abnormal sound, the machine must be stopped for check.The reasons must be found and the faults must be removed.

Sand vibrating screen Shaker sieve machine Separator Working principle of vibratory Screen:

The vibrating screen consists of screen box, supporting device, vibration exciter, transmission part, etc. The barrel-type vibration exciter is installed in the middle part of the machine. During normal operation, the vibartion of exciter will drive the screen mesh fixed on the screen box vibrate, and then materials will be screened. The big and small materials fall from the upper side and lower side of the screen to get them separated.

Sand vibrating screen Shaker sieve machine Separator Technical parameter:

| Model | Screen size (mm) | No. of Layer | Screen mesh (mm) | Max. feed size (mm) | Handling capacity (t/h) | Motor power (kW) | Vibrating frequency (r/min) | Double swing (mm) |

| 2YZS1548 | 4800×1500 | 2 | 3-100 | 400 | 30-275 | 15 | 870 | 5-9 |

| 3YZS1548 | 4800×1500 | 3 | 3-100 | 400 | 30-275 | 15 | 870 | 5-9 |

| 2YZS1848 | 4800×1800 | 2 | 3-100 | 400 | 56-330 | 18.5 | 870 | 5-9 |

| 3YZS1848 | 4800×1800 | 3 | 3-100 | 400 | 56-330 | 18.5 | 870 | 5-9 |

| 2YZS1860 | 6000×1800 | 2 | 3-100 | 400 | 65-586 | 22 | 870 | 5-9 |

| Packaging Detail:Standard container and sea-worthy package or in bulk. |

| Delivery Detail:10 working days |