Railcar Platform Vibrators

| Condition:New | Place of Origin:Oregon United States | Brand Name:PMF | Type:External |

| Drive Mode:Electro-Hydraulic | After-sales Service Provided:Engineers available to service machinery overseas | Fast:Unloads rail cars in seconds without stopping the unit train. | Effective:Transmits frequency through the strongest member of rail car.. |

| Quiet:The quietest rail car vibrating unloading system available. | Low Maintenance:Creates no damage to itself or the rail cars. | Cost Effective:Cuts operating and maintenance costs. | Versatile:Unit is adaptable to all types of rail cars and unloading systems. |

Vibrating Railcar Platforms

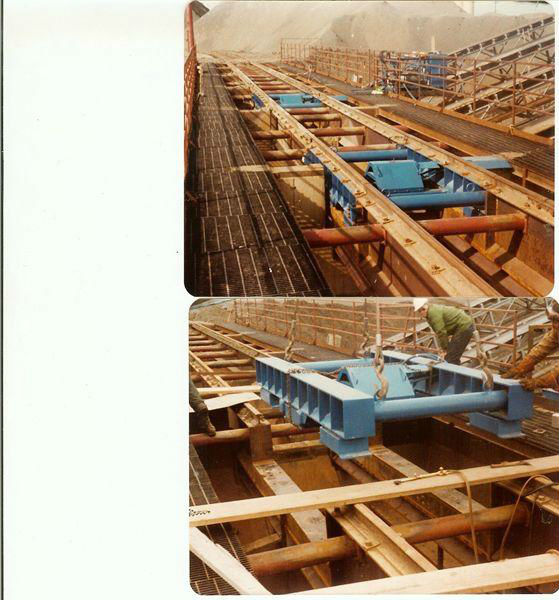

Vibrating Railcar PlatformsfromInnovative Hydraulic Designs(I H D)are adaptable to all types and sizes of rail cars and unloading systems (even rotary dumpers where vibration is required to unload frozen or wet sticky materials). Rail cars are unloaded by moving them across a series of high frequency, variable speed, hydraulic vibrating platforms without stopping the train. It should be noted that the rail cars are not violently shaken in this process.

The platforms are operated on the frequency of the material which allows the material to discharge freely. Partially frozen or wet materials may require the rail cars to be spotted on the platforms and vibrated. Extremely frozen materials would require an optional hydraulic ram to be installed on each platform. The ram would engage the rail cars main beam and then be vibrated. The system shown unloads an 80 car bottom dump unit train with manually operated doors in 1-½ hours (with 85 tons per car of pit run material). Ambient temperature range is -20°to +50°C.

Vibrating Railcar Platformscut operating and maintenance costs significantly, are versatile and adaptable to containers, trucks, rail cars, etc. and are the quietest rail car unloading system available on the market.

ISOLATION

Platforms are isolated from trestle or any other form of dump platform by eighteen 2" pins mounted in six isolation boxes. Feet of isolation boxes are welded to flange of beam. All hydraulic lines are isolated, and vibrator is covered to keep material from harming the vibrator and lines. Hard plumbing is used at all points except at the hydraulic pump unit and vibrators, a short flex line is used.

PLATFORMS

The speed of the unit train being unloaded is determined by the quantity of platforms installed, the length of the trestle and the type of rail cars. The system shown was set up to run four platforms. Test results showed that the train was able to be unloaded by moving slowly across two vibrating platforms. (Unloading speed doubled using 4 platforms). Difficult materials may require that a rail car be spotted on two platforms. The pumping unit can provide hydraulic power for up to four platforms with excess oil available to run bin vibrators, hydraulic flow control gates, etc.

Please send us your requirements and we will respond promptly with a No Obligation proposal.

| Packaging Detail:Shipping container |

| Delivery Detail:Ten to twelve weeks ARO. |