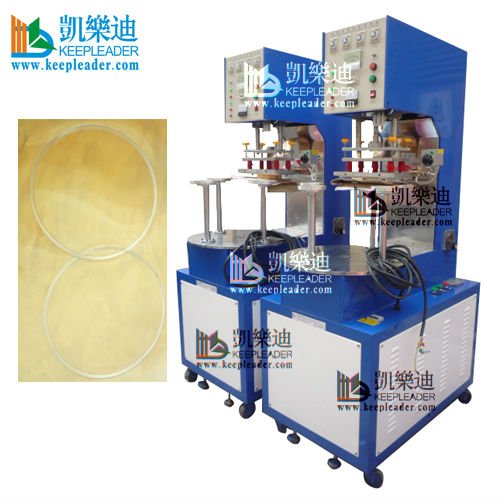

PVC/PLASTIC WELDING MACHINE,HIGH FREQUENCY WELDING MACHINE FOR BLISTER/CLAMSHELL/CLEAR CYLINDER BOX BOTTOM WELDING

PVC HIGH FREQUENCY WELDING, BLISTER HIGH FREQUENCY WELDING, CYLINDER BOTTOM HIGH FREQUENCY WELDING, PLASTIC HIGH FREQUENCY WELD - details see: https://www.machineto.com/pvc-plastic-welding-machine-high-frequency-welding-machine-for-blister-clamshell-clear-cylinder-box-bottom-welding-10053580

| Type:Blister Packaging Machine | Condition:New | Application:Food | Automatic Grade:Automatic |

| Driven Type:Electric | Voltage:380 | Power:5000W | Place of Origin:Guangdong China (Mainland) |

| Brand Name:HIGH FREQUENCY PLASTIC WELDING | Model Number:KLR-5000W,HIGH FREQUENCY PLASTIC WELDING MACHINE | Dimension(L*W*H):1.2*1.1*1.8 | Weight:500 |

| Certification:CE | Warranty:ONE YEAR GUARANTEE | After-sales Service Provided:Engineers available to service machinery overseas | HIGH FREQUENCY PLASTIC WELDING MACHINE:PVC/BLISTER HIGH FREQUENCY WELDING MACHINE |

PLASTIC WELDING MACHINE, HIGH FREQUENCY PVC/BLISTER/CYLINDER BOX BOTTOM/PLASTIC WELDING MACHINE

ABOUT PRODUCT

Customized design; Safe and convenient operation

ABOUT FACTORY

Comprehensive management process, leading technology and service team

EXPERIENCE

Internationalization of business process; Rich experience of Non-standard design

AFTERSERVICE

Uniform standard with special difference for each, Professional and Experienced service

MARKET

Yearly 30% Market share increased, One-to-one service

High frequency Plastic welding machine

Application | |

Used for welding/sealing clear/transparent cylinder bottom(cylinder and disk), which is made of PVC,PETG, APET and PP by high frequency welding machine or ultrasonic welding machine, (Note: APET and PP is no better for high frequency welding), this machine also the best choose for blister/Clamshell welding/Sealing | |

Product Features | |

High Q value oscillation tube, stable and reliable for output the welding diameter is optional, 30mm up to 300mm qualified for different length of clear cylinder high frequency welding is stronger and beautiful for welding effect The machine is turntable feeding, automatic and manual operation is optional High sensitive anti-sparkle device NL5557 to avoid damaging the mould. High quality imported apparatus European-model high frequency vibration box, more reliable and stable in output High precision cam splitter for precision counterpoint Fully enclosed for operation position(optional) Mounted five caster with four brakes Automatic thermostat to keep the temperature at best performance in welding High precision high frequency knob for visible control Low voltage control panel for safe purpose Anodized mould and tooling for longer life span Top amounted cylinder for vertical pressure, which is more uniform Foot pedal control and button control is optional Over current protection circuit to avoid burning out the oscillation tube | |

Technique Specifications | |

Model | KLY-5000W |

RF power | 5kw |

Voltage | 220V,380V,50hz or 60hz |

Frequency | 27.12MHZ |

Electronic power | 8KVA |

Rectify | Silicon diode |

Oscillation tube | 7T85RB |

Max gap of electrode | 200mm |

Stroke distance | 175mm |

Size of upper electrode | 300*330mm |

Size of bottom electrode | 500*500mm |

Temperature | 30 up to 200 degree |

Welding time | 0 up to 10 seconds |

productivity | 4000/8hours |

Overall dimension | 1000*660*1730mm |

Standard equipment:

| Name | Origin | Brand |

| Air driven components | Taiwan | Airtac |

| AC contactor | Korean | LG |

| Relay | Japan | Omron |

| Electron Tube | Japan | Toshiba |

| Time controller | Taiwan | CKC |

The manufacturer will do endless improvement, please contact us for updated

| Packaging Detail:PLYWOOD CAES,HIGH FREQUENCY PLASTIC WELDING MACHINE |

| Delivery Detail:6 DAYS,HIGH FREQUENCY PLASTIC WELDING MACHINE |