Pharmaceutical Sorbitol Processing Machine

| Place of Origin:Tianjin China (Mainland) | Brand Name:MecKey | Model Number:MK | Application:Liquid |

| Type:Starch derivatives processing machine | After-sales Service Provided:Engineers available to service machinery overseas | Material:SS 304/316L | Capacity:5000-120000tpy |

| Worker Qty.:12-15 persons per shift | Finished Project Qty.:26 pcs | ROI:1.6-2.8 years | Process:Hydrogenation process |

| Product:VC grade sorbitol & daily use sorbitol | Dry solid content:69-71% | Construction Area:2000-5200 m2 | Delivery Time:3-4months after getting the down payment |

Pharmaceutical Sorbitol Processing Machine

Capacity: 5000-120000tpy

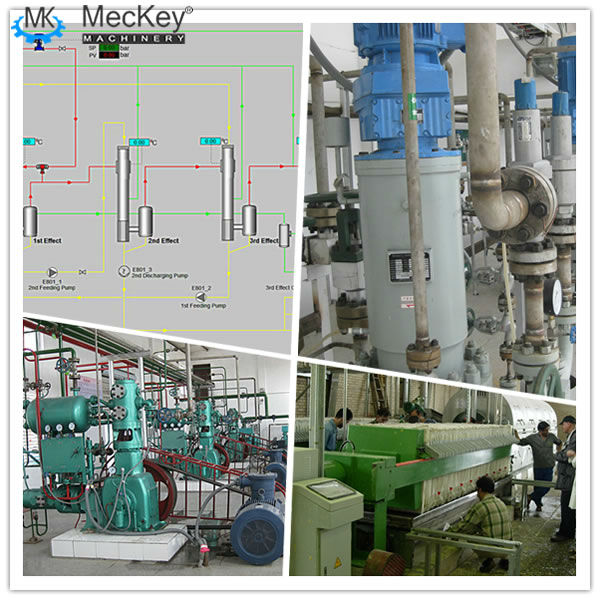

Process flow block diagram

General process description and the photos for the main equipments:

(1) Glucose syrup adjustment: Glucose syrup coming from crystal glucose plant is adjusted to the qualified DS with water.

(2) Decoloring and filtration: The qualified glucose syrup is sent to the decoloring tank for decoloring with active carbon input. After that the AC will be removed by the filter, and the syrup will be sent to the next section.

(3) Ion exchange: Tiny foreign items and bad odor is removed via ion exchanger. Then, the material will be qualified to the hydrogenation section.

(4) Hydrogenation: After burdening, the qualified material is sent to the reactor with aid of high pre. H2. By the reaction, the material will be turned to the crude sorbitol. Then the material is sent to the flash tank for cooling. And then it will be sent to the sedimentation tank.

(5) Sedimentation and filtration: After sedimentation tank, the accelerant is separated from the crude sorbitol, then recycled and reuse. The material is sent to the next section after filtration.

(6) Decoloring and filtration: The crude alcohol is sent to the decoloring tank for decoloring with active carbon input. After that the AC will be removed by the filter, and the syrup will be sent to the next section.

(7) Ion exchange: Tiny foreign items and bad odor is removed via ion exchanger. By this way, the material will be turned to be qualified.

(8) Evaporation: The qualified sorbitol is totally cleaned through safety filter, then it is sent to evaporator for concentrating to reach the required DS as final product.

| Packaging Detail:Sea worthy package |

| Delivery Detail:4 months after getting the down payment |