OKK clay brick making machines clay brick logo machine

| Place of Origin:Fujian China (Mainland) | Brand Name:OKK | Model Number:HT | type:clay brick logo machine |

| lenght:250cm | height:250cm | width:220cm |

1.logo making machine

2.logo making machine

3.clay brick stacking machine

4.new logo machines

5.highly quality clay bricks

1. Clay Basic PropertyRequirement:

The Clay must fulfill the below basic property requirements in order to produce good quality of Clay Brick.;

Base Situation | Level Requirement | Applicable Scope(%) | |

| Name | Item | ||

Chemical Composition | SiO2(Silicon Dioxide) | Suitable | 55~70 |

| Allow | 55~80 | ||

Al2O3(Aluminum Oxide) | Suitable | 10~20 | |

| Allow | 5~25 | ||

Fe2O3(Ferric Oxide) | Suitable | 3~10 | |

| Allow | 2~15 | ||

| CaO(Calcium Oxide) | Allow | 0~15 | |

| MgO(Magnesium Oxide) | Allow | 0~5 | |

| SO3(Sulphur Trioxide) | Allow | 0~3 | |

| Ignitionloss | Allow | 3~15 | |

Calcareous Contents | <0.5mm | Suitable | 0~25 |

| 2~0.5mm | Allow | 0~2 | |

2. Area Requirement :

For the HT-400 Clay Brick Making Production Line to set up, the area needed will be at least30m x 20m(600m²)of flat ground, these is only for the machineries part, still not including clay storing area, office building area, workers hostel area and kiln area.(Kiln area will have to depends on which type of kiln customer choose to build)

3. Working System:

We will base on every year working for 300days, everyday working for1 shifts(8 hours)for our customer reference.(Kiln workers will have to depends on which type of kiln customer choose to build then only can decide);

| No | Operating Post | 1st Shift | 2nd Shift | 3rd Shift | Total | Remarks |

| 1 | Loader Driver | 1 | - | 1 | skill | |

| 2 | Clay Supply Machine | 1 | - | 1 | normal | |

| 3 | Grinding Mill | 1 | - | 1 | normal | |

| 4 | Power Stirring Mill | 1 | - | 1 | normal | |

| 5 | Clay Extruder | 1 | - | 1 | skill | |

| 6 | Cutting Machine & Parting Machine | 1 | - | 1 | normal | |

| 7 | Center Control | 1 | - | 1 | skill | |

| 8 | Electrician | 1 | - | 1 | skill | |

| 9 | Maintenance Technician | 1 | - | 1 | skill | |

| 10 | Shift Leader | 1 | - | 1 | skill |

4Production Process:

5Production FlowIntroduction;

lWorkers use Loader or manually input the Clay from Clay Storage Area into Clay Supply Machine.

lClay Supply Machinewill crush andstirringthe Clayand then supply it to the first Belt Conveyor.

lThefirstBelt Conveyor. will transport the Clay into the Grinding Mill.

lGrinding Millwill crush and grind theClay then unload it into thePower StirringMillinstall below.

lPower StirringMillwill mix well the Clay with water and thensupply it to the second Belt Conveyor.

lThesecondBelt Conveyorwill transport the Clay into the Clay Extruder.

lClay Extruderwill process and extruding the ClayintoClayColumnandsend it to Cutting Machine.

lCutting Machinewill cut theClayColumnintopreferencessize and send it to Parting Machine.

lParting Machinewill part the Clay Cakeinto production sizeClayBrick needed to produce.

6. Production Main Processing Equipments:

TechnicalCharacteristic &Parameter

HT-Clay Supply Machine | |

| Power | 7.5KW-6 |

| Length | 800mm-1200mm |

| Capacity | 15 m³-40m³ |

HT-Grinding Mill | |

| Power | 13KW-6 x2 |

| Fast roll speed | 280 rpm |

| Slow roll speed | 270rpm |

| Feeder granular | ≤20mm |

| Clearance between rolls | ≥2mm(adjustable |

| Capacity | 20-30m³/hour |

HT-2.5m Power Stirring Mill | |

| Power | 30KW-4 |

| Working stirring lengt | 3000mm |

| Matting reducer | JZQ500 |

| RPM | 48rpm |

| Capacity | 30 m³/hour |

HT-360 Clay Extrude | |

| Capacity | 8,000-10,000pcs/hour(standard brick) |

| Vacuum degree | ≤92% |

| Host machine power | 90KW-4 |

| Extruding pressure | 2.0MPa |

| Total weight | 6500kg |

HT-Automatic Cutting Machine | |

| Motor power | 1.1KW-6 |

| Cutting length | 1250mm (adjustable) |

| Discharge velocity | 0.09m/second |

HT- Parting Machine | |

| Motor power | 5.5KW-6speed regulating motor |

| Cutting frequency | 15 times/minute |

| Knockout stroke | 430/mm |

| Cutting numbe | 22pcs/time(solid brick) |

7.The company honor wall:

8.recommended products:

a.clay roof tile making machines:

b. logo machine:

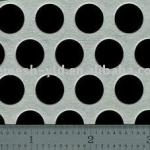

c.clay brick pictures:

d.biomass granulation machine:

e.biomass burner:

| Packaging Detail:wood case |

| Delivery Detail:30 working days |