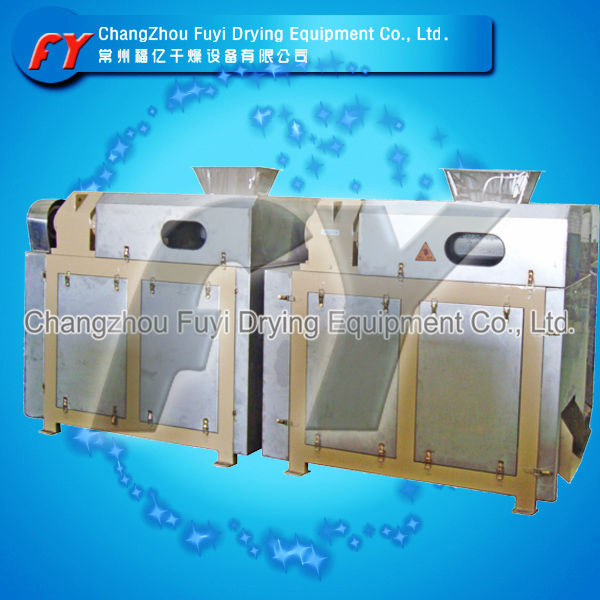

NPK Fertilizer Dry Granulation Plant

| Machine Type:Granulator | Condition:New | Product Type:Fertilizer | Place of Origin:Jiangsu China (Mainland) |

| Brand Name:FUYI | Model Number:DG200 | Voltage:380V/220V | Power(W):15KW |

| Dimension(L*W*H):1330*930*1464mm | Weight:2 tons | Certification:We can provide CE | After-sales Service Provided:Engineers available to service machinery overseas |

| Application:Fertilizer Granulation Plant | Machine Material:Carbon Steel or Stainless Steel | Sample Test:Available | Color:Any color you require |

| Hardness:8-20N | Recyclable:yes | Adhesives:no | Roller material:CrMo |

| Capactity:0.9-1.2t/h | Demension:1165*800*1248mm |

NPK Fertilizer Dry Granulation Plant

Fuyi offers a proven range of machine sizes for high pressure granulating, which covers nearly all requirements of the clients.

Working principle

Raw materials are sent into hopper by fixed quantity feeder, when two rolls parallel each other horizontally, powder materials are continuously and evenly fed in the gap between two rollers by their gravities and forced compression, The intermediate products are bar shape, then the crusher will crush the bar shape products into irregular granules, finally using rotary screen to sieve the final products, qualified products will be put into bags, unqualified products will be recycled mix with new material for the next granulating process.

A completely dry granulating process includes the following equipments

1. Automatic feeding system

2. Auto-measuring batching and mixing system

3. Extruding and pelletizing system

4. Complete pellet smashing system

5. Screening and materials returning system

6. Auto-packaging and control system

7. Dust collector system

Examples of granulating materials

1. Fertilizers:

potassium sulfate(SOP), potassium chloride, the Russian red potassium, NPK fertilizer, ammonium chloride, potassium nitrate,Ammonium Phosphate Monobasic(MAP),Diammonium phosphate(DAP), ammonium sulfate, ammonium bicarbonate, cow manure plus sulfur, humid acid etc.

2. Powders:

zinc oxide,Bentonite, benefication agent, phosphate rock, aluminum fluoride Calcium Hypochlorite,calcium chloride, calcium phosphate, cryolite,TSP, SSP,antioxidant, potassium carbonate, rubber additives, metal powder, fillers, feed additives, silica, pharmaceutical intermediates, steel-making additives, lead oxide, melting agent, clay , steelwork dusts, etc.

3. Carbon Black / Graphite

4. FGD gypsum

5. Chemical powder:Sodium formateHCOONa, Magnesium acetate.

Rollers available in various materials and Final shape granular

Technical parameters

Motor power: 15kw

Reducer: Adopts hard tooth surface dedicated reducer

Double pressed rollers: Forged with alloy steel, heat treatment in special process, the surface of the

press roll can be plated with hard chromium to have rust proof and wear-resistant treatment.

Hour output: Oblate shape 900-1300 kg/h, irregular shapes 200-500 kg/h

Rate finished product: Oblate shape 60-90%, irregular shapes 30-60%

Pellet diameter: 3.8, 4.5, 5.0, 5.5, 6.0, 6.5, 8, 10mm

Shapes of pellets: Oblate, strip or slice, square, bow shape, irregular shape

Dimension of DG200 granulator: 1165*800*1248mm

Weight: about 1.2 T

Inorganic moisture content: 2-5%, Moisture content of organic material around 6-12

Working temperature: Normal temperature

Layout of Fuyi Roller Presses

Powder are entered into a roller press and compacted between the rollers to a strip with high density.

We can design different diagram for different clients, we need to design the layout according our clients provide us some basic information about the size of their factory, and how do they want to place the equipments. Our target is making the process more simple , more easy, more economic and more effective.

Granulating with roller presses

During briquetting a granular, material is compacted between two counter-currently rotating rolls. Forming of briquettes is without any binding agent.

Auxiliary Equipments

Advantages of NPK granulator

Adopting increased shafts output dedicated reduce and drum gear shaft coupling effectively protects the rolls and the main bearing from damage, increase the driving efficiency and further improving the production of products. One roller’s bearing seat is fixed and the other roller’s bearing seat is sliding.

In the surface of the roller, many holes are arrayed. According to the different compression rate of the materials, choose the trough of one roller aiming at the trough of another roller, or peak to trough. Two rollers are arranged in horizon.

With the supporting pressure of hydraulic cylinder, they are close to each other and the hydraulic system can has the multiple and automatic protection function.The optimizedhydraulic system makes the motion flexibility of dynamic rollers stronger and be able to reject the iron lumps mixed in unexpectedly and protect the equipment to run safely.

Roller pulling with roller removal device, it’s more easily and quickly for you to change the rollers, and save your costs of changing.

Different clients, Different tests

Delivery

Customers Installation Site

Electric Cabinet

Services

Fuyi has designed and manufactured roller presses and equipments for briquetting and compacting NPK fertilizer, powder, chemical, minerals, etc, since 2006. We take care of green field projects as well as of existing plants. Our services cover material tests, process layout, engineering, and supply of complete granulating plants or key equipments, guidance of installation and commissioning, training.

Also, the company manufactures and supplies equipment for drying equipments and dust collector machines.

Extensive experience and best quality production facilities guarantee a smooth workflow from start to finish.

Welcome our sincere clients come to visit out factory.

| Packaging Detail:1. Big machines packed in nude.2. Spare parts packed in wooden case.3. If our clients have any special requirement, we will pack as request. |

| Delivery Detail:50 days after we receives deposit. |