Magnetic Separation Process

| Condition:New | Type:magnetic separation process,ore dressing | Place of Origin:Henan China (Mainland) | Brand Name:zhongke-magnetic separation process |

| Model Number:CTB series | Product Name:Magnetic Separation Process | Energy:Low power consumption. | Application:ore, coal, construction materials benefication. |

| Installation:technician guidance provided. | Warranty:12 months start from the date finishing installation. | Certificate:ISO9001:2000, CQC,BV. | Facility visiting:Available. |

| Customized:upon request. | Motor Power:1.5-7.5 kw |

Magnetic Separation Process

Magnetic Separation Process is suitable for wet magnetic separation of materials such as magnetite, calcined ore, etc. and it can remove the iron in the coal, non-metal and construction industries. The magnetic system is made from high quality ferrite magnetic materials and /or rare earth magnet steel. On the shell surface, the magnet intensity is 100-600mt. The wet type permanent magnet cylindrical separator is commonly used for iron ore separation. It is suitable for separating materials with high magnetism. In recent years, it has been used as concentrating equipment in place of magnetic dewatering cell.

It has the following advantages: short magnetic circuit, little magnetic flux leakage, high magnetic intensity, low energy consumption, fine beneficiating results, simple structure and easy to maintain.

Magnetic Separator:

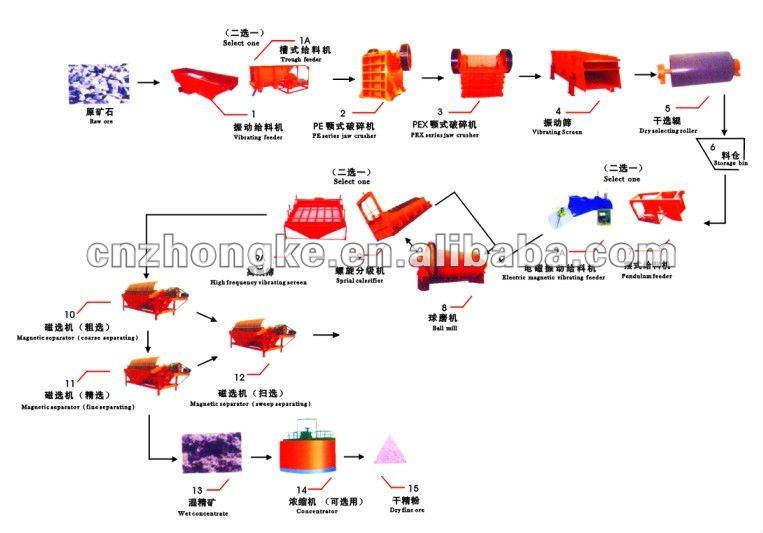

Red iron, brown iron magnetic separation process flow:

About Us:

Henan Zhongke Engineering & Technology Co., Ltd. is specialized in heavy equipment like various crushers, magnetic separators, mining machines, bricks and blocks machines, cement production line, AAC block line, etc., which is located in the middle of China. Our competitive price, high quality products and excellent after-sales service had gain us good reputation in this field.

Company Picture and Certificates:

| Model | Shell Diamete r(mm) | Shell Length (mm) | Rotary speed of shellr (min) | FeedingSize (mm) | Processing Capacity (t/h) | Power (kw) |

| CTB6012 | Φ600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

| CTB6018 | Φ600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

| CTB7518 | Φ750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

| CTB9018 | Φ900 | 1800 | <35 | 3-0 | 40-60 | 3 |

| CTB9021 | Φ900 | 2100 | <35 | 3-0 | 45-60 | 3 |

| CTB9024 | Φ900 | 2400 | <28 | 3-0 | 45-70 | 4 |

| CTB1018 | Φ1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

| CTB1021 | Φ1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

| CTB1024 | Φ1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | Φ1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

| CTB1224 | Φ1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

| CTB1230 | Φ1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

| Packaging Detail:Nude packing, spare parts in wooden case. |

| Delivery Detail:15-25 days after receipt deposit. |