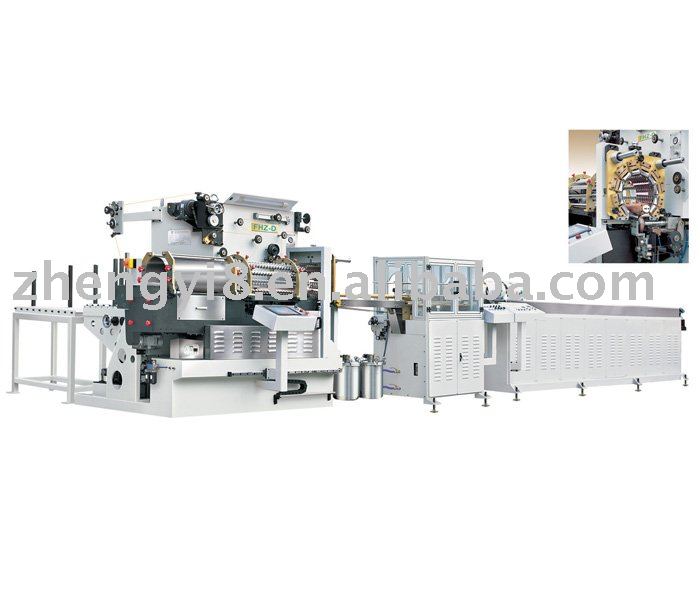

low carbon tin can making machinery for coating can

| Condition:New | Application:Chemical | Automatic Grade:Automatic | Driven Type:Electric |

| Power:refer detail | Packaging Type:Cans | Packaging Material:Metal | Place of Origin:Guangdong China (Mainland) |

| Brand Name:zhengyi | Model Number:fhz-d | usage:tin can welding | Type:Packaging Line,Coating Machine |

low carbon tin can making machinery for coating can

1. technology progress

cutting---rouding---welding---coating---drying---pre-curling and expanding---flanging---seaming bottom---beading and curling

2.picture of production field

(1) fully automatic welding (has the rounding function)

(2) inner and outer coating

(3) high frequency induction drying

(4) pre-curling and expanding

(5) flanging

(6) seaming bottom

(7) beading and curling

detail:

| model | FHZ-D |

| applicable can diameter | Φ260~Φ290mm |

| applicable can height | 180~ 395 mm |

| working capacity | 30~45Cans/min |

| seaming landing | 0.9 mm |

| welding speed | 9~24 mm |

| welding frequency | 100~260 Hz |

| Tin thickness | 0.28~0.38 mmT2-DR8 |

| wire dinameter | Φ1.5 mm |

| cooling water | >20 L/min >400 Kpa/cm2 <18 |

| pressed air | >800 L/min >500 Kpa/cm2 |

| total power | 22KVA |

| dimensions | 2250×2290×2000mmL×W×H |

| wieght | 3000Kg |

| Internal/external coating machine | |

| model | GNWT-D |

| applicable can diameter | Φ260~Φ290mm |

| working width | 10~15mm |

| working capacity | 16m/min |

| power consumption | 650W |

| Dimensions | 2530×1000×1550mmL×W×H |

| weight | 500Kg |

| High-frequency drying machine for large size tank | |

| model | GHG-D |

| applicable can diameter | Φ260~Φ290mm |

| drying speed | 16m/min |

| High-frequency current | 300~1300Aadjustable |

| total power | 25KVA |

| dimension | 5100×830×1150mmL×W×H |

| weight | 1000Kg |

Our major component suppliers:

1. Pneumatic elements are purchased from Japanese “SMC”

2. Hydraulic elements are purchased from Taiwan precision brand

3. Electronic control devices are purchased from “Schneider”, “Omron” and some domestic suppliers

4. Worktable surface is produced by #304 stainless steel gold plated

5. Machine surface paint is purchased from “NAVECO” car paint

| Packaging Detail:wooden case |

| Delivery Detail:30days |