Hot sale continuous waste Tire / tyre recycling machine with CE, SGS, ISO, TUV

| Condition:New | Type:Tire Machine,continuous | Tire Machine Type:Tire Recycling Machine | Place of Origin:Henan China (Mainland) |

| Brand Name:JINPENG | Model Number:XY-9 | Voltage:380 | Power(W):110KWH |

| Weight:30MT,30mt | Certification:CE, SGS, ISO, BV, TUV | Warranty:2YEARS | After-sales Service Provided:Engineers available to service machinery overseas |

| capacity:8-20tons daily | fuel:oil or natural gas | manpower:2/shift | heating method:hot air |

| installation space:60m*30m | working pressure:slightly negative pressure |

Advantages:

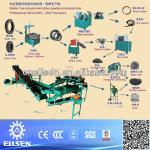

1.Continuous waste Tire/tyre Pyrolysis Plant

2. CE,SGS,ISO, BV, TUV on both quality and environment, no pollution to meet your strict emission standards,

3. 28 years experience in this oil and equipments manufacture fields.

4. We ensure that we will reply to your salesafter questions within 12hours, and show our solution project within 24hours.

5. Life time maintenance, we have engineers overseas for your any problems if you can not solve your problems with our internet guidance.

Outstanding Features:

1.. - Advanced technology, full automation.

2.. - Large capacity, high oil yield, good oil quality, high profit.

3.. Low cost in operation. No need energy to heat the reactor, generated sync gas is enough,less manpower.

4.. Low requirement on the raw materials, no need tiny granule, 10cm pieces acceptable for smooth running.

Main parts list of the continuous waste Tire / tyre recycling machine:

Security of the continuous waste tyre/tire recycling machines:

1.. Satisfied quality during manufacture: both sides of the steel with slope surface forfull welding, and 4 times welding totally done to ensure the best quality.

A. For inside part of the reactor, first welding after rolling to regulate and fix thereactor by hand, second manual welding for filling, third welding for overlay.

B. For the outside part we adopt automatic submerged welding technology forstabling and appearance.

2.. Checking: all of the weldings will be detected by the ultrasonic nondestructivetesting method to ensure the welding quality and the welding shape. Drive immediate corrective actions when problems occur.

3.. All of the containers such as the tanks, gas separators, condensers, etc. WILL

be tested after manufacture to ensure NO LEAKING AT ALL.

4.. we adopt manufacture process controlling system on the quality, safety is a personal responsibility; reinforce safety awareness at every opportunity. Every part of the manufacture process are charged by one professional person and oneauditor. Every manufacture process, manufacture date, operators, etc. Can be checked by records.

Environmental-friendly:

Emission Standard: Adopting special gas scrubbers to remove acid gas and dust from smoke, meeting environmentalprotection standard; the smoke after scrubberslooks like steam. As for the emission standard, please refer to our SGS emissionreport.

Smell during operation: Fully enclosed during the operation, only white steam fromthe chimney can be seen, no smell except the rubber or oil itself taste during thefeeding or pumping out or in from the oil tanks.

Water pollution? During the operation, the water we use is recycling one to cooldown the gas-oil and convert into liquid oil in the condensers. No pollution at all.

Solid pollution? the solid after pyrolysis is the crude carbon black and steel wires

which can be deep-processed or sold directly with its value.

| 1 | Suitable Raw Materials | Small pieces of Waste tyre,rubber, waste plastic≤10cm |

| 2 | Operating Mode | Fully Continuous Operation |

| 3 | Reactor Rotational Speed | 1R/M |

| 4 | Loading and discharging | automatic feeding and discharging under high temperature |

| 5 | Noise dB(A) | ≤85 |

| 6 | Main Reactor Weight (MT) | About 18Mt |

AFTER SALES SERVICE for our machines:

1.. Quality warranty period: 1~3 years warranty for the main reactor of pyrolysis machines and the chamber of the distillation machine according to different models, and lifetime maintenance for complete set of machines. Engineers available for oversees service, any problem you need us to be in your site, we will send engineer to you.

2.. According to the requirement of the buyer, our company sends engineers for installation and commissioning in buyer's site including the training of skills of buyer's workers on operation, maintenance, etc.

3.. Supply layout according to buyer's workshop and land, civil works information, operation manuals, etc. to the buyer.

4.. All of the parts damaged during operation, we supply at cost price.

| Packaging Detail:continuous waste Tire / tyre recycling machine with CE, SGS, ISO, TUV:2*40'HC+1*40'FR |

| Delivery Detail:within 70 days after the first deposit |