High Qulity Wood Drier,Inaccordnce With ISO9001:2000

| Condition:New | Place of Origin:Hebei China (Mainland) | Brand Name:DX | Model Number:GZ-6.0II-DX |

| After-sales Service Provided:Engineers available to service machinery overseas | Type:High frequency heating+ vacuum drying | Model:3,4,6,8,10 cubic meter | Power:From 10 KW to 30 KW |

| Control:Full-automatic | Color:Could be tailor made as requires | Certificate:ISO 9001:2000 | Advantage:No crackings,color change,rapid heating |

| Note:Special size could be tailor made as per request | Size:6465*1916*2006mm | Component:High frequency generator and vacuum drying oven |

High Quality Wood Drier,Inaccordnce With ISO9001:2000

High Frequency Vacuum Wood Drieris the result of design combining High frequency medium heating technology and Vacuum cryogenic dehydration technology. The working principle of HF medium heating: in the high frequency electrical filed, friction of medium molecule generates heat. Keeping the wood in the frequency electrical filed, thus the inside & outside of wood will be rapidly heating. Meanwhile, vaporizing temperature of water will be decreased under vacuum conditions.

DXHF vacuum wood drier adopts high frequency drying, inside and outside of wood timber is heated at same time,uniform heating,high speed drying,short timeandgood quality, which may keep the timber nature color, meanwhile,the timber is aerated under the vacuum environment, non-cracking,especially applied for the thick and hard precious wood, wet wood.

Advantages of high frequency vacuum wood drier:

Quick heating--- It does not require heat conduction,inside and outside of wood timber is heated at same time;

Fast dehydration---During the heating process, there is staged temprature difference between inside and outside of wood timber this will speed up the water movement from inside wood to outside wood;Drying time is1/5compare with tranditional wood drying method.

High quality--- there will beno crackings ,bending and color changeby taking control of heatiing speed,relative vacuum degree & condensing rate.

Strong adaptability---High frequency-Vacuum drying can realize not only cold drying but hot drying, help to eliminate stress,solidify resin. This applies to dry all kinds of wood

High-usage---Square designeddrying box supplies more space utilization. it is suitbale for different shaped wood

Cost saving--- Fast tempreture raise and higher sapce utilization takes lower cost than traditional ways.

Eco-friendly--- This machine does not pollute the enviroment

Full-automatic---UA UnAttended Automatic drying process,very easy to handle

Specification of high frequency vacuum wood drier:

operating principle: HF medium heating plus vacuum dewatering

Size: 6465*1916*2006mm

Power input: 20 kw

Drying medium: direct heating

Heating mode: electrical medium

Application: drying all kinds of wood

Temperature range: subject to request

Water evaporation: 180kg/24hours (according to follow conditions:density of wood 0.75, output power 20KW, temperature of condenser:30 °C , vacuum degree— 0.08MPa )

Types: manual, automatic

Capacity:6 m3, --------optional: 3 m3, 4 m3, 8 m3, 10 m3

| Model | Power | Effective Volume | Applications | Max Length of Wood | Outer Size |

| GZ-3.0II-DX | 10KW | 3m3 | all kinds of wood | 3m | 4330*1716*1806mm |

| GZ-4.0II-DX | 10KW | 4m3 | all kinds of wood | 4m | 5330*1716*1806mm |

| GZ-6.0II-DX | 20KW | 6m3 | all kinds of wood | 5m | 6465*1916*2006mm |

| GZ-8.0II-DX | 30KW | 8m3 | all kinds of wood | 6m | 7605*2016*2006mm |

| GZ-10.0II-DX | 40KW | 10m3 | all kinds of wood | 6m | 7605*2116*2106mm |

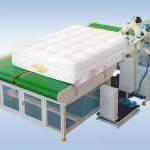

Sample Photos

| Packaging Detail:plastic and foam packing,fixed by wood pallet, shipped in container by sea |

| Delivery Detail:within 20 days max... |