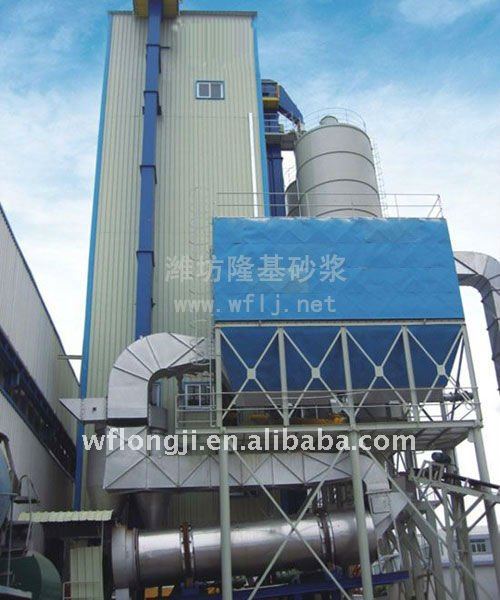

high quality vertical-type dry-mixed mortar production line

| Place of Origin:Shandong China (Mainland) | Brand Name:Longji | Model Number:Vertical | property:good |

The production line is an automatic production line of ready-mixed dry mortar, which consists of material supply, automatic

measuring ingredients, mixing materials and efficient, pulse dust,

automatic weighing packaging, electrical and automatic control system components.

Specifications

Dry Mortar Production Line produces

1.Masonry mortar

2.Plastering mortar

3.Interface mortar

4.Self-leveling mortar...

Types of Dry Mortar

1 Masonry mortar

2 Plastering mortar

3 Ceramic tile binder

4 Thermal insulation mortar

5 Heated board matching mortar

6 Gap filler

7 Interface mortar

8 Decoration mortar and powder coating

9 Self-leveling mortar

10 Floor mortar

11 Gypsum joint mortar

12 Waterproof dry-mixed mortar

13 Non-shrinkage grouting material

14 Repair mortar

15 Hardening and artistic floor mortar

Introduction of Dry Mortar Production Line

Our company is specialized in dry-mixed mortar mixing plant, which introduces international and domestic advanced technology and equipment. The maxing brickwork, plastering wall, pasting tiles, floor tiling, stone plate and floor mat.

Dry mortar is powdered or granular mixtures of aggregate, inorganic cementations materials and functional additives. It is made up of sand, cement, thickening powder, fly ash and admixture. Also, add strong and efficient additives according to requirement. Transporting in bulk or packaged available, it can be used directly after mixing in proportions.

Mixing System

Introducing advanced technology, weightless biaxial slurry leaf mixer or imported uniaxial pear-type mixer features high precision and fast speed, low energy consumption and sealing operation.

Dedusting system

All powdery materials is in process under the closed state, while feeding, batching, scaling, adding, discharging and packaging. Fully closed mixing unit can reduce pollution of dust and noise to the environment effectively.

Control systems

Computer control of automatic and manual make the operation simple and convenient Dynamic Panel show the running of components, store a variety of data, Print various statement according to requirement.

Drying systems

Adopt three-cylinder dryer in drying system, with high efficiency and low energy consumption.

Technical Parameter of Dry mortar production line

Introduction of Dry Mortar Mixing Plant

| MODE | CAPACITY | AREA | REMARK | |

| Simple | 1~15t/h | 40 m2 | Manual batching and packing | |

| Basic | 5~15t/h | 40~60m2 | Manual batching, automatic packing | |

| Semi-automatic Serial | 5~15t/h | 40~80m2 | Automatic batching of coarse material, manual batching of additive, automatic packing | |

| Semi-automatic Tower | 5~50t/h | 40~100m2 | Automatic batching of coarse material, manual batching of additive, automatic packing | |

| Fully Automatic Tower | 5~100t/h | 60~500m2 | Automatic batching of raw material and packing |

| Packaging Detail:Normal |

| Delivery Detail:Within 60 Days |