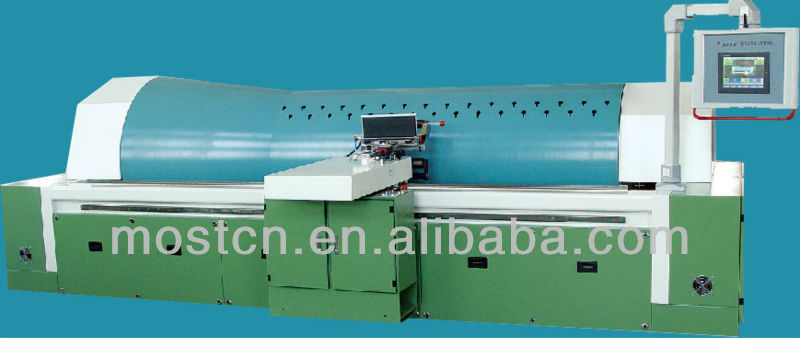

HF928High Speed Sectional Warping Machine

| Condition:New | Type:warping machine | Application:warping | Production Capacity:10 800 |

| Place of Origin:Jiangsu China (Mainland) | Brand Name:Most | Model Number:intellegent | Weight:2500kg |

| Power(W):11kw | Certification:CE | Warranty:2 years | high speed:1 |

HF928 High Speed Sectional Warping Machine

Main Characteristics

It's a preparatory to weaving lines of wool textile, trademark, heavy twist synthetic fiber, filament,

yarn dyed fabric, natural silk, terry tower and industrial special fabrics. It can be completed with

water-jet, air-jet, rapier and gripper looms, and is an excellent substitute of similar products of

Europe.

·High level electric configuration: MITSUBISHI PLC, PANASONIC servo system, API step motor,

DIGITAL touch screen computer workstation.

·Fully computerized automatic control for input data of yarn, automatic calculation, precise

displacement of warping table, high intelligence

·Beaming tension presetting function ensure perfect winding result

·Big touch screen, clear, rich information content, easy operation, displaying detailed warping

condition and trouble shooting for electric, hydraulic and air components.

·Start point locating and section alignment to be set easily by one key.

·Advanced field bus technology for easy transmission of any signal from any part of the machine,

fully automatic operation for testing, trouble shooting and parameter setting.

·Pneumatic car-use disc brake, reliable and large brake moment.

Main Characteristics

·With the increasing thickness of the yarn, warping table controlled by independent imported

step motor move backwards automatically to ensure the constant space between front reed

and yarn surface.

·Head stocks horizontal movement controlled by the servo motor. Leasing reed and creel is

fixed. The central of warp yarn section is always in beeline thus to ensure even tension of

both section sides.

·Broken end position auto-memory function.

·Liner type guide ensure precise warping table displacement in two directions.

·Integrated warp beaming device suitable for big beaming tension, fit for all types of beams.

·Fixed 1:6 conical drum, made of sheet steel, high precise dynamic balanced, fit for all types

of yarns.

·Pneumatic three-point automatic positioning leasing reed, high efficiency and function in

short time.

·Guard rail and infrared raster available for guarantee safety of beaming operation.

·Electric broken end stop motion device.

·Multiple types of creels for option.

·Cone ends and cone pitch to order.

·Multiple types of tensioners for option.

·Oiling / waxing device and static eliminator available for option.

Main Technic Data

1 Working width: 2300mm-3600mm

2 Beam diameter: 800mm, 1000mm, 1100mm for option

3 Warping speed: 10 – 800(m/min)

4 Beaming speed: 0-160m/min

5 Braking distance: ≤2.5m ( 500m/min )

6 Drum diameter: 1000(mm)

7 Drum tapering : 1:8 for beam dia. 800mm; 1:6 for beam dia.1000mm and dia.1100mm

8 Work station for beaming control: 10.4-inch real color touch screen

9 Section traversing speed: 0.001-9.999mm/r,adjustable steplessly

10 Section positioning accuracy: ≤0.01(mm)

11 Section traverse accuracy: ≤0.01%

12 Section width: 20mm – 360mm or to order

13 Tension scope: 0-600(N)

14 Displacement measurement accuracy of winding density: 0.001(mm)

| Packaging Detail:wooden pack |

| Delivery Detail:within 30days after received prepayment |