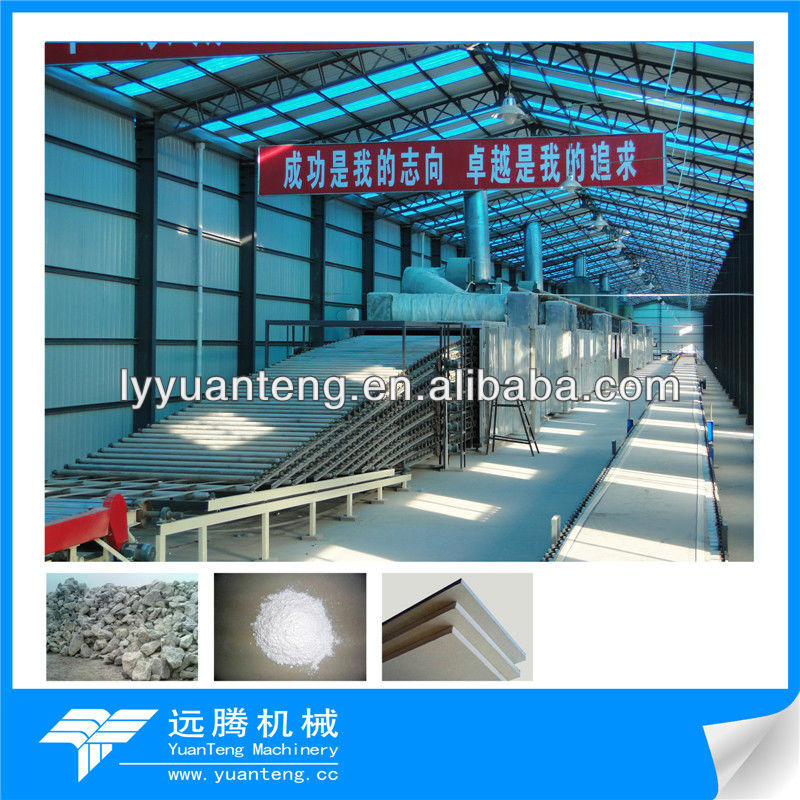

full automatic gypsum board production line

| Condition:New | Application:construction | Production Capacity:99% | Place of Origin:China (Mainland) |

| Brand Name:YT | Model Number:YT10M | Voltage:380v | Power(W):50HZ |

| Features:stable | Certification:ISO CE | Warranty:1YEAR | After-sales Service Provided:Engineers available to service machinery overseas |

| automatic:high degree | annual capacity:2-30million sqm | technology:German |

Linyi Yuanteng Machinery Co.,Ltd has been engaged in designing and manufactureing in gypsum production line for more than 15 years. (we established in 1995),accumulating rich experience in equipment designing,manufacturing,installaing and debuging.

Gypsum board production line:

1.Take annual capacitty of 10 million sqm gypsum board production line for example;

(based on thickness of 9.5mm gypsum board) Machine working:24 hours per day and 300 work per year

| No. | item | unit | Target | Qty/yr | |||||||

| 1 | Capacity per year | M2 | 10million. | ||||||||

2 | Main raw materials | semi-hydrated gypsum powder | kg/m2 | 7.0 | 70000T | ||||||

| water | kg/m2 | 0.476 | 4760T | ||||||||

| Shielding paper | kg/m2 | 0.39 | 3900T | ||||||||

| modified starch | kg/m2 | 0.04 | 280T | ||||||||

| Foam agent | kg/m2 | 0.0062 | 62T | ||||||||

| White glue | kg/m2 | 0.004 | 40T | ||||||||

| additives | It depends | ||||||||||

3 | Fuel consumption | Coal (6000kcal/kg) | kcal/m2 | 3800 | burning rate 80% | ||||||

| Oil (11000kcal/kg) | kcal/m2 | 3800 | 3500-4000t/yr,Depends on local light oil heat value | ||||||||

| Gas (8500kcal/ m3) | kcal/m2 | 3800 | |||||||||

| 4 | electricity | kwh/m2 | 0.2175 | 2175000KWH | |||||||

| 5 | Compressed air(10kg/cm2 ) | M3 | 5 m3 /min | ||||||||

| 6 | Area needed | The factory covers an area of 18000 ~ 28000 square meters (including yard, roads, the dispatch area, parking lot, etc.) Building structure area: ~6000-10000 square meters (including production workshop and warehouse) Production workshop: width (13 - 15 m) height (6-8 m) length (220-240m) Finished products storeroom: width (24 - 30 m) height (6-8 m) length (220-240m) | |||||||||

| 7 | Installed power | KW | 630 | ||||||||

| 8 | labor | people | About 50 people, not including management, maintenance and production technical workers. | 3 shifts | |||||||

| 9 | Annual working days | day | 300 | 8hr.×3 | |||||||

2.After sales service:

.We offer Technical Support until the workers know how to operate.

.We provide free answers about all kinds of questions about the production,if necessary,pls call us freely.

.We provide lifelong guidance about our equipment.visit client in regular times.

.Provide equipment easy-broken pasts year in year.to insure your machine can working continuously.

3.Guarantee: 12months from the date of finishing installation. The last 2% of value can be paid after one year,

for the quality guarantee period. Need open quality guarantee letter.

Ms Smile 0086 1565535001

| Packaging Detail:containers.ship or railway.it will need about 4-20containers,which depends on production capacity. |

| Delivery Detail:equipment production period:90days |