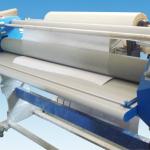

Frequency drive foil paper laminating machine

| Type:Laminating Machine | Condition:New | Place of Origin:Hebei China (Mainland) | Brand Name:Huasheng |

| Model Number:HS-600 | The length of product:600mm-1400mm. | Control system:Pneumatic control | Temperature:PID control |

| Automatic correction:Material saving. |

Frequency drive foil paper laminating machine

Introduction

The unit is aimed at600 mm --1400mmwith single or double base material base,through flow delay,compound and molding products .It uses paper,film,aluminum foil,kraft paper,

nonwoven fabric,woven fabric,woven bags,etc.as base material,polyethylene or polypropylene as raw material,by casting to laminate single sided or casting a single substrate,substrate to synthesize new material.

Main Technical specifications

| Laminating host power | AC380V,three phase four wire |

| Composite host power | AC380V, three phase four wire |

| Total power design | 68KW |

| Average power | 20kw----40kw |

| Composite linear speed | 15—60m/min |

| Composite optical axis diameter*length | Ø450mm(±5mm)*1600mm |

| Composite silicone shaft diameter | Ø215mm±5mm |

| Barrel screw material | 38rMoALA Nitriding treatment Screw surface spraying alloy |

| Length of die mouth | 1350mm |

| Width of laminating | 600mm---1150mm |

| Thickness of laminating | 0.015mm---0.05mm |

| Mould material | 40Cr |

| quantity of air flow | 0.6m/min³ |

| Tracheal diameter | Ø8 |

| (Cycling) softened water | 0.5m³/min |

| Work environment | Non-corrosiveness,no explosive gas. ambient temperature:0°C--40°C |

| relative humidity (RH) | ≤85%(without water) |

Advantages:

1.Composite parts and rewinding parts can achieve ganged frequency-converting,make the speed steady.

2.Composite parts of pneumatic control saves time and effort.

3.Electric roll up,pneumatic pick roll,non-stop rolling change,reduce labor intensity.

4.Cycle device,input the cooling water and output the used water in the same time.

5.The mould is imported chrome steel material,deform not easily,make the film uniform.

6.Automatic feeding and drying equipment,make the product smooth and have no bubbles.

7.Cooling roller,the most advanced cooling function.

The pictures of the machine's products

Laminating paper

Laminating aluminum foil

pe & kraft paper:

pe & nonwoven fabric

Hebei Huasheng Plastic & Rubber Machinery Co.Ltd.is a professionoal,manufacturing company,with a number of independent intellectual property rights of independent import and export.The company own nearly 4,000 squre meters factory,registered capital of 5 million,total assets of RMB 10 million.

| Packaging Detail:wooden case |

| Delivery Detail:45 days after receiving the 30% desposit |