FILTERK Cement Industry Bag Filters

| Condition:New | Efficiency:99.99% | Construction:Cement Industry Bag Filters Cartridge | Filtration Grade:Hepa Filter |

| Medium Material:Polyester Cement Industry Bag Filters | Porosity:0.3-0.5um | Place of Origin:Jiangsu China (Mainland) | Brand Name:FILTERK Cement Industry Bag Filters |

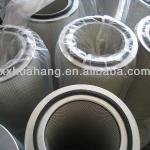

| Model Number:Cement Industry Bag Filters | Dimension(L*W*H):153*2000(mm) | Certification:ISO9001:2008 | Cement Industry Bag Filters:FILTERK Cement Industry Bag Filters |

| Description:Cement Industry Bag Filters For baghouse transformation | Filtering area:4.6m2 | Service life:≥6 months | Operating temperature:≤135℃ |

| Filtering precision:0.3-0.5μm | Diameter:153(OD)*2000(H) | OEM:Yes |

FILTERK Cement Industry Bag Filters

Feature of Cement Industry Bag Filters

u 100% fine sand bonded polyester

u Wide and shallow pleated

u A variety of specifications for customers to choose

u Filtration efficiency up to 99.99%

u Integrated design,quick and easy installation, maintenance

u Suitable for a variety of tube sheet specifications

u Top and bottom are pouring with special materials

u Surface can be special treatment, like PTFE coating, anti-static etc.

Application environment of Cement Industry Bag Filters :

| 1.Cement and rock |

| Crush/Grind Coal mill Raw mill/Cement mill Clay crushed Packaging machine Bentonite crushed Kaolin processing Ventilation and dust removal of silo top Material handling / shipping |

| 2.Aluminum plant |

| Fluidized bed dry-cleaning tower The venturi jet dry-cleaning tower Self-baking dry-cleaning tower Carbon dust processing Broken and ventilation of anode Reaction / non-reaction mine shafts prebaked |

| 3.Food / Medical |

| Food Additives Cereal drying Protein spray drying Grain processing Flour Animal vitamins Sugar-coated tablets |

| 4.Metallurgy |

| Electric arc furnace Blast furnace Sulfur removal furnace Casting machine Induction furnace Mold cooling line Blasting / Polishing Drum furnace Sand production/recycling |

| 5.Chemical industry |

| Fertilizer spray drying Plastic fiber Bleaching powder Cellulose Polyethylene resin Polystyrene staple Coke / briquettes processing Packaging line Tire / Special rubber PVC Catalyst processing |

| 6.Paint / Pigment |

| Black powder mixing / agitation Packaging line Pneumatic conveying Paint mixing Pigment stir Spray drying Micro powder mill |

Specification and model of Silo Top Filter :

| Model | Specification | Filtration Area |

| AS-1 | OD153mm*Length1000mm | 2.3m2 |

| AS-2 | OD153mm*Length2000mm | 4.6m2 |

| AS-3 | OD324mm*Length660mm | 9.4m2 |

| AS-4 | OD324mm*Length915mm | 11.2m2 |

| AS-5 | OD352mm*Length660mm | 9.4m2 |

| AS-1-PTFE | OD324mm*Length660mm | 4.6m2 |

| AS-2-PTFE | OD352mm*Length660mm | 5.1m2 |

| Applicable apertures for a variety of top-mounted standard tube sheet,including: |

| 118mm 152mm 127mm 159mm 133mm 164mm |

| Bottom-mounted standard specifications,including: |

| 118mm 146mm |

| Packaging Detail:Packing of Cement Industry Bag Filters : Cartons of 5-layer corrugated paper. We can also meet our customer's special requirement. |

| Delivery Detail:7 days |