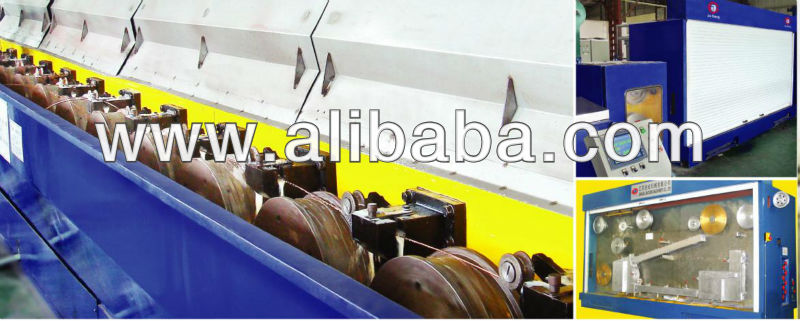

electric cable production line

| Condition:New | Place of Origin:Istanbul Turkey | Brand Name:KARMA | Model Number:KRMEC110 |

| Voltage:220 | Power(W):410KW | Weight:45 TON | Dimension(L*W*H):1.9m 1.35m 1.75m |

| Certification:ISO CE TSE | Warranty:2 YEAR | After-sales Service Provided:Engineers available to service machinery overseas | ELECTRIC WIRE MAKING MACHINE:ELECTRICAL CABLE MAKING MACHINE |

1. Main Technical Data

1.1. Inlet diameter: 8 mm

1.2. Outlet diameter: 1.30~4.5mm

1.3. Number of drawing pass: 13

1.4. Diameter of drawing capstans: 450mm

1.5. Max delivery speed: 25m/sec (Normal running speed at 18~22m/sec, 8~18m/sec. during annealing)

1.6. Annealing mode: by DC current of 5000A and voltage of 65V

1.7. Type of annealer: Horizontal layout

1.8. Speed ratio between drawing capstans: 1.279~1.15; for die 1~9, 1.279; for die 12~13, 1.05~1.26

1.9. Bobbin-change speed: 6~12m/sec. (automatic bobbin-change at preset length)

1.10. Size of take-up bobbin: PND500/PND630

1.11. Max. traverse width: 460mm

1.12. Main motor: Z4-315-42, 250kw, DC, 600 rpm

1.13. Motor for final capstan: Z4-200-21, 75kw, DC, 1500 rpm

1.14. Take-up motor (2 No.s): Z4-132-2, 22kw, 3000rpm

1.15. Total power: about 410kw

1.16. Consumption of compressed air: 6m3/h 0.5MPa

1.17. Volume of cooling oil tank: 20 m3(to be prepared by user)

1.18. Overall dimension: 23750×5000×4510mm

1.19. Total weight: 43 tons

2. Composition and Specifications of Main Components

2.1. JD-LHD450 high speed copper wire drawing machine (straight row and rapid change of dies)

2.1.1 Die size: ø42×32mm (National standard)

2.1.2. Type of finish die: Rotary

2.1.3. Die threading inching: 3 pedal switches with anti-reverse device

2.1.4. Gearbox cooling and lubrication:

Gear oil pump: GBZ-50, 3kw, 50L/min, 2.5MPa

Heat exchanger: tubular cooler GLC4-13 13m2, tubular cooler (horizontal layout)

2.1.5. Cooling and lubrication for wire drawing:

Emulsion pump: ISL80-65-160, 7.5kw, 11.5 L/sec.

Heat exchanger: GLL5-25/0.63L, 25m2tubular cooler

Filter: SLQ-65, duplex barrels and net type, 0.4~0.6 MPa

Water consumption: 1000 L/hr.

Volume: 20 m3(To be prepared by user)

| Packaging Detail:WOODEN CASE and PE FILM PACKING |

| Delivery Detail:90 DAYS |