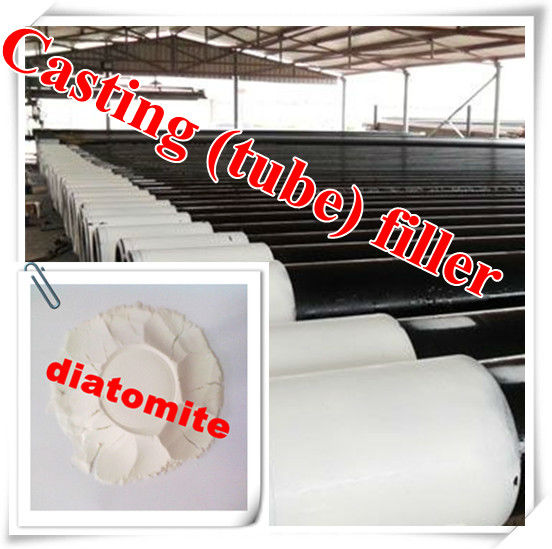

Diatomite filler control the cooling rate of castings (tubes)

| Processing:Other | Place of Origin:China (Mainland) | Brand Name:SYD | Model Number:SYT |

| NAME:diatomite powder ;diatom | shape:powder | SiO2:65% | Al2O3:5% |

| Fe2O3:1.5% | Color:brown or white or yellowy or pink powder | Moisture:0.5% | LosOn Ignition:3% |

Diatomite additive for Casting

Diatomite with good quality

Resonable price

Prompt shipment

The attitude of sincere cooperation

1,Specification

Physical properties | Chemical properties | ||

| Name | diatomite filling materials | SiO2 | ≥65% |

| Color | brown or white or yellowy or pink powder | Al2O3 | ≤5% |

Type | Calcined Diatomite | Fe2O3 | ≤1.5% |

| Flux Calcined Filter Aid | |||

| Moisture | ≤0.5% | MgO | ≤0.4% |

| LosOn Ignition | ≤3% | Others | ≤0.8% |

| PH | 5-10 | Pb, mg/kg | <0.4 |

| Bulk Density | <0.40g/cm³ | Water Diffluence | <25mg/l |

| Permeability (Darcy) | >0.8~12.0 | As, mg/kg | <0.5(5ppm) |

| CAS NO. | 61790-53-2 | Heavy Metal | <0.005% |

The mentioned data of analysis just for reference, the actual result depends on physical material loaded. As natural mineral products, the mentioned product is non-toxic, harmless, non-smell, it is safety in transportation , and it has no any harm to person.

2,Application:

1), the centrifugal casting (tube) special coating diatomite contained filler

Diatomite treated with the appropriate technology, binder, suspending agent and additives prepared by centrifugal casting (tube) coatings can be adjusted to the thermal resistance of the casting system, control the cooling rate of castings (tubes), and thus play to extend the heat mold centrifugal casting mold used in life and to ensure that the microstructure and mechanical properties of casting to meet the requirements.

2), outside the building (inside) wall paint Diatomite functional fillers

Unique porous particle structure in the coating, the use of diatomaceous earth can make a smooth coating of high rough, resulting in the effect of the back light, not only that, the cohesive force of the diatomaceous earth can also adjust the balance of the coating and substrate surface, in addition, due tothe porosity of the diatomite make sticky paint will soon dry.

3), the rubber industry Diatomite functional fillers

Diatomite unique particle structure to enable it to act as a reinforcing material, can partially replace carbon black in Silicone rubber machinery and rubber products.

4), the pesticide industry

Diatomite application for pesticide powder filler advantages: PH value neutral, non-toxic, performance suspension, the adsorption performance, light weight, 135% of the oil absorption, fineness of 325 mesh and -500 mesh, mixed farmers to usenot blocked, can play in the soil insulation, loose soil, extend the efficacy fertilizer time, improve soil, contributing to the effect of crop growth.

5), compound fertilizer industry

Fruits, vegetables, flowers, and a variety of crop fertilizer. Application the diatomite advantages: adsorption performance, light weight, fineness, PH value neutral non-toxic, mixed fertilizer application of diatomaceous earth to become an effective fertilizer, prompting the growth of crop material, soil improvement.

| Packaging Detail:Conventional packing ton bag (1000kg per bag), or 25kgs PP woven bag with PE inner liner |

| Delivery Detail:Within 10 working days |