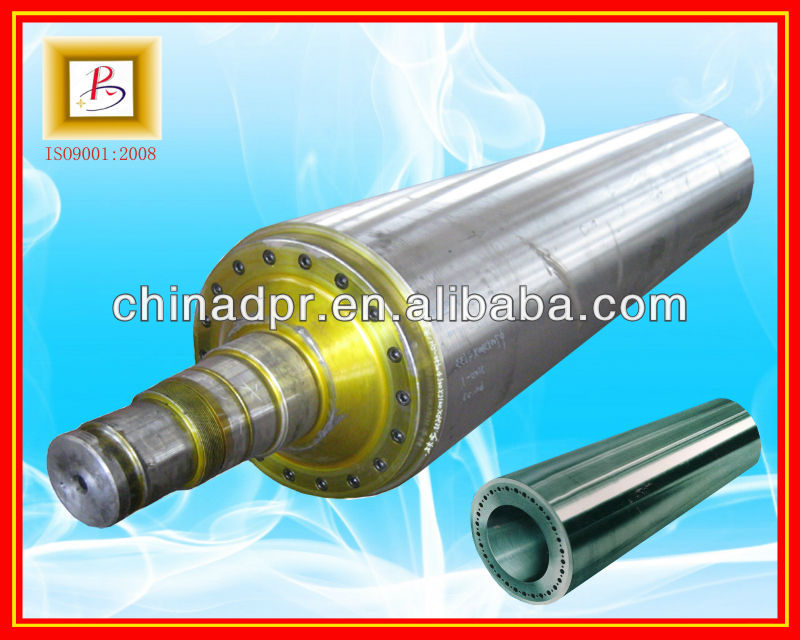

CuCr/NiCrMo Alloy chilled cast iron rolls, Calender roller

| Place of Origin:Liaoning China (Mainland) | Brand Name:DPR | Model Number:ALL | Material:Alloy cast iron, NiCrMo, CuCr, |

| Process:Centrifugal and Gravity pouring | Apply:Rubber,Plastic and Paper industries | Styles:Assembled,Cored,Drilled rolls | Roughness:Ra0.8 to Ra0.1 |

| Chilled Hardness:Hs72+/-2 | Chilled Thickness:6-25mm | Pressure Test:10 to 15 kg water pressure, keep 30minutes | Working Diameter:From 305mm to 930mm |

| Roll Strength:over 250MPa |

Chilled Cast Iron Rolls

- INTRODUCTION:

We are supplyingchilled cast iron rollsfor rubber industry, plastics industry, paper industry and other industries.

The rolls are made of special cast iron. The working surface of the rolls is chilled cast, forming a very hard and excellent wear-resistant shell. We are supplying rolls cored, drilled, or ssembled.

The rolls can be supplied as casting, or as wholly machined ones including turning, grinding, drilling. keyway cutting, thread taping etc. The working surface of the rolls can be ground cylindrically or crownedly. We are making groove rolls as well. We are using either the ordinary

gravity pouring process or the centrifugal pouring process,

or a combination of both processes. Customers are free to choose which process they prefer. The centrifugal pouring process for big size rolls is a recently developed pouring process. The notable advantages of the rolls made by centrifugal pouring process vs rolls made by ordinary gravity pouring process are as follows:

1.The chilled cast shell and the inner part of the rolls can be poured separately. Thus different composition of iron for the shell and for the inner part can be chosen freely according to different requirements.

2.The thickness and the hardness of the chilled cast shell can be controlled more precisely and uniformly.

3.The molten iron is condensed under the centrifugal force. The surface of the shell is free from porosity, sand hole, slag inclusion, or other casting defects.

When the roll is made by ordinary gravity pouring process, there is always a layer of mottled iron formed between the white iron(chilled cast iron) and the gray cast iron. When a drilled roll is used, this mottled cast iron layer always makes the drilling very difficult. When the roll is made by centrifugal pouring process, there is no mottled iron layer formed at all. The mottled iron layer problem no longer exists. The drilling can be done easily and precisely.

When proper materials are used and centrifugal pouring process is adopted, the hardness of the chilled cast shell can hold as high as HS 74+/-2. The tensile strength of the roll can reach as high as 250 MPa. The working life of the roll made bycentrifugal pouring process

would bethree to five timesthe working life of the rolls made by ordinary gravity pouring process

The sizes of rolls we are supplying are: (Diameter X Working Length in mm): 305x760; 360x1500; 400x1000; 450x1200; 480x800-1500; 510x800-1600; 550x1500; 560x1530-2000; 610x1730-2500;650x2130; 660x2130-3000; 700x2500-3500; 800x2500-4000; 930x2500-4000;

1.Alloy chilled cast iron rolls

2.Centrifugal Pouring

3.Chilled layer 6 to 25mm

4.For rubber and plastic mill

5.Smooth Ra0.4

| Packaging Detail:1. Anti-rust oil covered the whole rolls2. Plastic bag3. Reinforced Wooden cases, |

| Delivery Detail:30 TO 55 Days after received the Order |