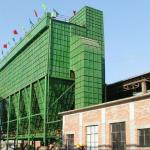

Crushing plant Dust collecting system

| Condition:New | Type:Fabric Dust Collector | Efficiency:99.9% | Minimum Particle Size:Meet the requirements of JB/T8532 |

| Place of Origin:Zhejiang China (Mainland) | Brand Name:TRUEMAX | Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas |

Pulse Bag Dust Collector,

Dust Collector, Bag Dust Collector, Dust Catcher

Based on overseas advanced technology and our practical application,HRdown flow style filter cartridge dust collector has been continually improved. The advantages are as follows: the first one is the dust collecting efficiency up to 99%; the second one is that it is a fine dust collector used to dust removing and filtering requirements of various working conditions; the third one is that it can clean the dust on the surface of the ultrafine, wet and fibrous filter materials with a removal rate of over 95%; the last one is that it is an equipment of simple construction, small in size, convenient maintenance and long service time.

Scope of application: metallurgical, building material, chemical, electric power, medicial,

nonmetallic, tobacco, food processing, plastics, abrasive, drying, powder spraying and weld fume fields etc;

1.ZXMC series bag-type Dust Catcher is a collection of purifying equipment developed for many fileds covering mine mining, grinding,electro smelting,machinery casting,chemical products,building materials,cement(Cement GrindingMill) ,waste incineration,food processing with large flow ,high concentration and irregular dust emission characteristics of working conditions.

2. It meets the requirements of Two and Three class areas under GB16297-1996;

3. The filter has the advantages of high dedusting efficiency, small amount of maintenances, long service life, elegant appearance, and etc;

4. It has selection and purification functions;

5. It can be widely used in many fields of mining operations, electric furnace melting, and machinery manufacturing, chemical products, building materials, cement (cement grinding mill), waste incineration and grain processing, and etc,.

6. It has offseted the defects of negative pressure for Cyclone Dust Collector, and positive pressure for Bag Filter as well.

7. ZXMC Dust Collector, national patent product, adopts compressed air as clean power. There are blowing pipes on top of every row of filter bags which make a pulse net. PLC appoints the definit program to let compressed air go into filter bags through 6.4mm nozzles, then filter bags inflate instantaneously and dust layer falls. Meanwhile, the air current reverse and dust in the filter bags is blown out.

8.This bag-type electronic filter set pulse and cyclones as a whole collection against mining & quarrying with high dust concentration and mass contamination characteristics.

9. Products are widely used in electricity, metallurgy, chemical, building materials and architectural engineering industries

| Model | Weight | Number of element | No. of filter cartridge | Filter area | Length*Width*Height | |

| 3C-12T | 1720 | 1 | 12 | 120 | 1021*2275*4513 | |

| 3C-24T | 2600 | 2 | 24 | 240 | 2042*2275*4513 | |

| 3C-36T | 3640 | 3 | 36 | 360 | 3063*2275*4513 | |

| 3C-48T | 4840 | 4 | 48 | 480 | 4084*2275*4513 | |

| 3C-60T | 6100 | 5 | 60 | 600 | 5105*2275*4513 | |

| 3C-72T | 6860 | 6 | 72 | 720 | 6126*2275*4513 | |

| 4C-16T | 2130 | 1 | 16 | 160 | 1021*2275*4513 | |

| 4C-32T | 3100 | 2 | 32 | 320 | 2042*2275*4996 | |

| 4C-48T | 4270 | 3 | 48 | 480 | 3036*2275*4996 | |

| 4C-64T | 5580 | 4 | 64 | 640 | 4084*2275*4996 | |

| 4C-80T | 7000 | 5 | 80 | 800 | 5105*2275*4996 | |

| 4C-96T | 8360 | 6 | 96 | 960 | 6126*2275*4996 | |

| Packaging Detail:Main machine naked,electric motor, and control box packed by wood box |

| Delivery Detail:30 days after receiving down payment. |