coal mine shaft hoist

| Place of Origin:Henan China (Mainland) | Brand Name:lzzj | Model Number:designed according to the contract | Condition:New |

| After-sales Service Provided:Engineers available to service machinery overseas |

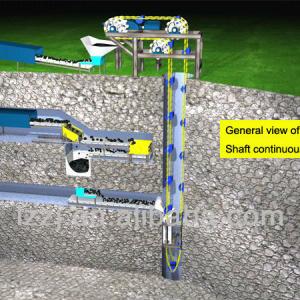

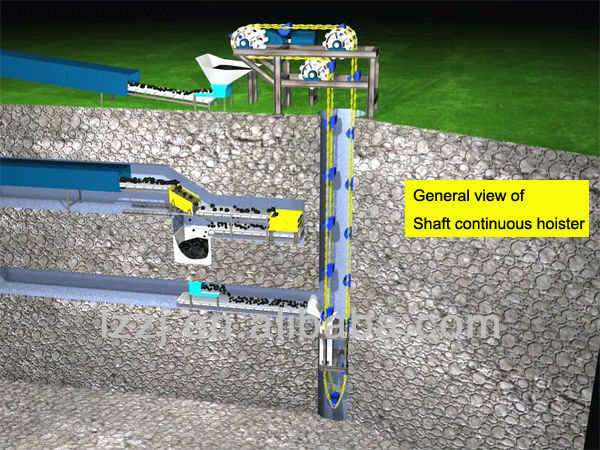

Mine shaft continuous hoisting equipment

Continuous hoist is mainly composed of rotary small skip , improve bearing fitting, active commutation unloading device, direction changing device, transfer system and pre-treatment system. By the existing main shaft hoist, the continuous hoist in difference is that the container size is reduced, the number is increased, the operation mode is changed from alternating direction into a continuous, and the speed is reduced. The tipping point can be not only placed away from the wellhead, but also placed near the wellhead. And the hoist can be vertical transportation , and short distance horizontal inclined transportation as well. Compared with the existing ordinary type hoist, the continuous hoist’s hoisting capacity changes in a wilder range, its continuous mode is changed into rotation from stationary, its bearing force center line coincides with the bearing center. At last, compared with clamping type belt conveyor, the difference is that the bearing parts are unitization or simplification.

Characteristics of the continuous hoist (compared with the existing hoist)

1. High efficiency: operation efficiency can be improved by 60%, and reduced the operating cost

by 50%.

2. Energy conservation: under the same lifting capacity condition, stick to the installed power

by 50%

3. Save money: can save capital investment(shaft construction)by 50%, mechanized equipment investment by 60%, electric control equipment investment by 80%.

4. Supermatic: fully system(loading, running, unloading)none-on duty automatic operation.

5. High security and reliability: no trouble with overwinding, squatting cage, slippery rope and overloading.

6. Save time: increase shaft building speed by 50%, save installation time by 60%, save servicing time by 40%

7. Large range of capacity expansion: by changing measurement distance, speed, load factors, running time utilization and other methods can greatly improve the productivity.

| Packaging Detail:designed according to the contract |

| Delivery Detail:designed according to the contract |