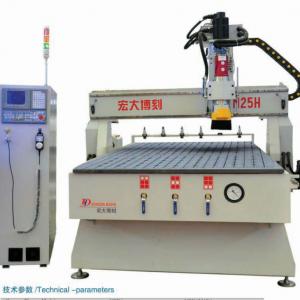

CNC Woodworking Center/table moving type/HSD air cooling spindle/Yaskawa servo motor

| Condition:New | Place of Origin:Shandong China (Mainland) | Brand Name:Hongda Boke | Model Number:HD-M25H |

| Dimension(L*W*H):1300*2500*200mm | Certification:CE ISO | Warranty:12 mouths |

Automatic Tool Changing CNC Wood Router Machine

Configurations of ATC wood cnc router

1. Taiwan Syntec control system.

2. Italy HSD air cooling spindle.

3. Improted Servo motor.

4. Germany ballscrew for Z axis.

5. High absorption vacuum table.

6. Auto-Tool Changing system.

7. High precision and long lifetime.

Equipment Features of automatic tool changing wood cnc router:

1. Separate keyboard control system:easy to learn and convenient to operate. the customer are able to master the application in a short time.

2. Advanced numerical control system and intelligent anti-transgress protection system: this function could prevent machine crashes when the design zone is beyond the process zone, intelligent process speed control:this function could control the process speed, which could increase the efficiency, prolong the cutter life and increase the rate if finished products.

3. Dust-suction system: the dust suction system could absorb the saw dust and keep machione clean, which maintains equipments as well; the dust system take place of the physical flat fixtion which save the time of load and unload time of slabs.

4. Advanced file pretreatment function can correct the error in the files and is compatible with the process codes of multiple national and international software (such as mastercam, type3, UG, caxa). advanced 3D space curve predition algorithm can make sure of the evenness of polyline and the speed and precision of curve lines.

Technical-Parameter of automatic tool changing wood cnc router

| Performance | Parameter | Optional | |

Stroke range | X axis | 1300mm | 1500mm/2000mm |

| Y axis | 2500mm | 2500mm/3000mm/4000mm | |

| Z axis | 250mm | ||

| Process precision | ±0.1mm | ||

| Reposition precision | ±0.05mm | ||

| Table structure | Vacuum suction(bar suction optional) | ||

| X Y Z structure | X Y gear rack, Z ball screw | ||

| Idle speed | >45000mm/min | ||

| Working speed | >20000mm/min | ||

| Spindle rate | 5.5KW | 9.0KW | |

| Spindle speed | 0-24000rpm/min | ||

| Motor type | Servo motor | ||

| Command code | G code | ||

| Working voltage | AC380V/50HZ | ||

| Operating system | SYNTEC |

Parts of wood cutting machine:

Imported linear square orbit and double slipper:

vacuum working table

Japanese Yaskawa servo motor:

imported ballscrow:

MACHINES:

BACK:

Front

Whole:

Applicable materials and industry of automatic tool changing cnc wood router:

1. Furniture: wooden doors, cabinets. Plate, office and wood furniture, tables, chair, doors and

windows.

2. The wood products: voice box, game cabinets, computer tables, sewing machines table,

instruments.

3. Plate processing: insulation part, plastic chemical components. PCB, inner body of car, bowing

tracks, stairs, anti-bate board, epoxy resin, ABS, PP,PE and other carbon mixed compounds.

4. Decorate industry: Acrylic, PVC, MDF, artificial, stone, organic glass, plastic and soft metals

such as copper, aluminum plate engraving and milling process.

Sample of cnc wood router:

For this machine the biggest working area can reach 2000X4000mm, we can produce the machine as the customer's different requirement, Sincerely lookinng for the agents all over the world

| Packaging Detail:wooden case |

| Delivery Detail:15 days after deposit |