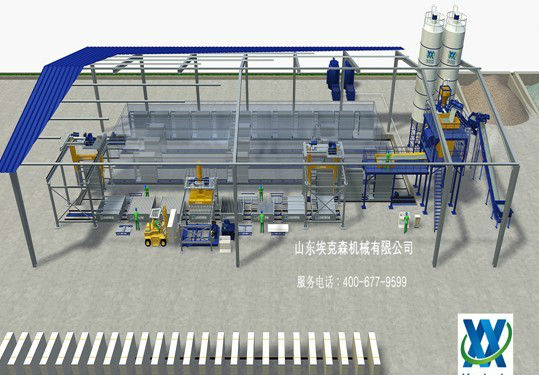

CLC block production line

| Place of Origin:Shandong China (Mainland) | Brand Name:EXXON | Model Number:E50 | After-sales Service Provided:Engineers available to service machinery overseas |

CLC block production line:

Technical Feasibility Analysis

1.1 Superiorities of EXXON Foam Concrete Blocks and Technologies

(I) Superiorities of Foam Concrete Blocks

1. Because CLC blocks have light volume weight, their structural weight per square meter is reduced. The volume weight is generally 500-1000kg/m³, so it can be afloat, which is 1/4 of solid clay brick and 1/2 of hollow block, and it can reduce 50-60% of wall load and 20-30% of structural weight per square meter, with rapid construction speed, so workers’ labor intensity and construction costs are decreased greatly.

2. With remarkable heat preservation and heat-shielding performance, building energy consumption is reduced largely. Its thermal coefficient is 0.08-0.27w/(m.k), which is ten times of clay brick, is warm in winter and cool in summer, decreases largely air-condition operation time, saves 30-50% of power consumption, and is the preferred walling material for the realization of building energy efficiency.

3. Excellent sound absorption and sound insulation performance. With multi-hole structure of evaporation-free foam, it possesses good sound absorption and sound insulation performance. Sound insulation amount for 240mm wall has decreased from 180 dB to 58dB, so it can completely achieve requirements for sound insulation of different households sharing the same wall.

4. With high impact strength, it can bear a sandbag with the height of 30 kg, and it can swing and impact for three times with a level difference of 0.5 kg.

5. As for suspension strength for single point, it can bear 1000N, and fissures will not appear within 24 hours.

(Ⅱ) Technological Superiorities of EXXON Foam Concrete Products

1. CLC blocks have wide raw material source, high utilization rate, and low cost. Fly ash, slag, sand, and ore sand are used as auxiliary materials (possessing any one of them is ok), and local materials are used, so construction cost is low.

2. CLC blocks have high technical content they can realize the effect of making bricks with air.

3. Simple technologies and easy for operation. Make use of special equipments and moulds.

4. Requirement for production conditions is not high. Simple and easy work sheds can be served as plants, products are stored openly, storages are not needed, and requirement for workers’ quality is not high.

5. Investment size is changeable and production mode is flexible. Namely, you can start from few mould and small investment, or do large-scale production directly.

6. Product features: energy conservation and environmental protection, sound insulation, heat insulation, water proof, fire protection, heat preservation, freezing protection, quake proof, increase of usable floor area, and long life etc.; with simple and convenient installation and excellent processing performance, it may not transform through sawing, digging, pegging, drilling, pasting, connecting, and punching, reduce labor intensity, accelerate construction progress, and save project total construction cost, which has met requirements of different customers for internal and external environment towards modern construction.

1.2 Technical Parameter Table for Foam Concrete Products

| Mark Number confirmed according to average density of concrete( kg/m³) | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| The max and min deviation of average density(kg/m³) | 250- 350 | 351- 450 | 451- 550 | 551- 650 | 651- 750 | 751- 850 | 851- 951 | 950- 1050 |

| Concrete thermal coefficient<(%) | 0.07 | 0.1 | 0.12 | 0.14 | 0.18 | 0.2 | 0.21 | 0.24 |

| Concrete grade according to compressive strength | B03 | B04 | B05 | B06 | B07 | B08 | B09 | B10 |

| Average compressive strength shall be less than (under 17% of coefficient of deformation) Mpa | 0.25 0.5 | 0.7 0.1 | 2.0 2.6 | 2.2 3.7 | 3.0 3.8 | 3.6 5.0 7.5 | 5.0 7.2 7.5 | 5.0 7.6 12.0 |

Quality standard: JC 1062-2007 Foam Concrete Block Industrial Standard National Building Material. Technologies of this project are newly utility patent technologies, and the vast majority of key technologies are initiates in China.

2. Technology Introduction

(1) The batching of material is computer-controlled which has high accuracy, good closure, no dust pollution and at the same time saves labor.

(2) Elevator shall send mixtures, such as cement etc., to pulping machine, mixing uniformly and forming cement paste.

(3) Add foaming agents to cement paste and mix cement paste foaming and foam fully, to produce foam cement paste. And then moulds shall be sent under blender through automatic system.

(4) Moulds through after pouring shall be sent to curing room after reshaping, to make them hard.

(5) Products after hardened shall be demolded in stripper sent by ferry push automatically.

(6) Products will be piled automatically by automatic stacker crane after stripper pushes products out of moulds, which shall be packed by packaging machine and delivered by forklift to the storage.

| Packaging Detail:packing for sea transportation |

| Delivery Detail:60 days after downpayment |