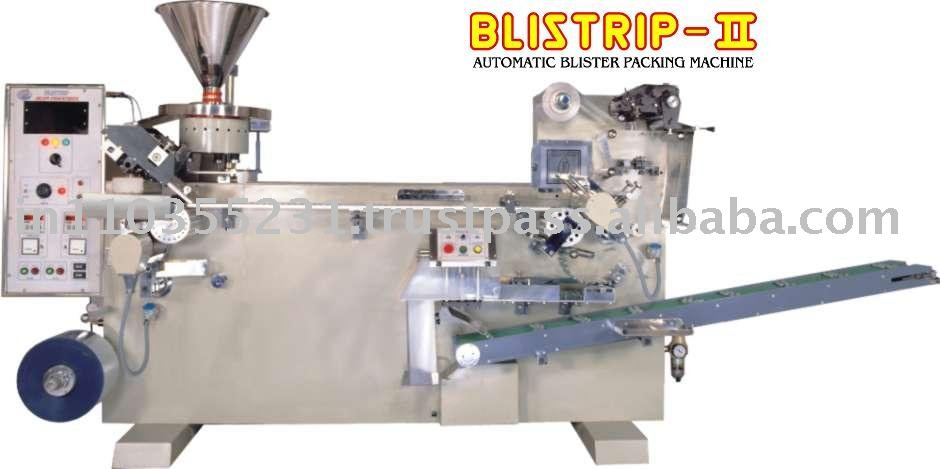

Blister Packing Machine

| Place of Origin:Maharashtra India | Brand Name:BLISTRIP | Usage:Capsule |

Blister Packing Machine

Efficiency: Blister Packing Machine has a competence and experience in package design ensures optimum utilization of machine capacity to give highest possible output as well as minimum possible packaging material consumption.

Performance: Blister Packing Machine is design in simplicity with careful placement of various stations giving operator full vision and total control of all principal functions that enhances performance.

Reliability:Solid Structure and sturdy components together with easy to set up and maintain mechanism ensures maximum availability. Quick and change over from one format to another improves productivity of Blister Packing Machine to satisfy market requirements.

Flexibility:The Machine can handle wide range of forming and lidding materials can equipment equipped with various types of f eeding systems to handle most types and shapes of pharmaceutical tablets/hard or soft capsules/pills in any presentation.

BLISTRIP - Ixt and BLISTRIP-II are automatic machine mainly utilised for packing of smaller and regular shaped solid articles such as pharmaceutical tablets, capsules, dragees etc., in blister packs.

The Blister Forming, Product Feeding and Sealing operations are continuous by rotary motion while the indexing and punching operations are of intermittent reciprocating motion.

The output capacity of the machine depends on the product characteristics and thus on the type of feeding device. In case of slightly curved or flat tablets upto 10mm dia an output of 150 packs per minute for BLISTRIP - Ixt or 300 packs per minute for BLISTRIP - II can be optimally achieved.

The packing materials namely PVC film and the lidding material namely Aluminum foil (or Glassine Paper foil) with heat sealable VMCH lacquer are required for blister packing and are drawn off from reel stock.

The blister packs which are punched out from main web can either be collected in bins or transferred over a conveyor belt for further handling. The trim waste is sheared off in small pieces to allow easy disposal.

Features:

High Speed, High Production, Cost Effective

Combi Packs For Better Utilization Of Capacity And Packaging Materials

Edge – To – Edge Cutting To Eliminate Trim Waste Between Packs

Special Tool Design Reduces Trim Waste

Continuous Blister Forming At Low Temperature By Contact Heating System

All Change Over Parts And Adjustments Accessible From Front Side

Compact – Occupies Less Floor Space

Built-In Water Chiller Facilitates Easier Operation

Extended Guide Track Can Accommodate Up To Four Feeders To Produce Multi-Product Kit Packs

Easy And Quick Change Over Reduces Material Wastage And Down Time

Simpler Operation Reduces Operator Fatigue – Increases Output

Technical Specification:

SPECIFICATIONS | |||

| Blistrip-100 | Blistrip-I | Blistrip-II | |

| MAX WEB WIDTH: | 104 mm | 148 mm | 210 mm |

| MAX. FORMING DEPTH: | 10 mm (EXTENDABLE TO 20) | ||

| MAX. OUTPUT* : PACKS / MIN : | 120 (1 UP) | 150 (1 UP) | 250 (2 UP) |

| 250 (2 UP) | 350 (3 UP) | ||

| MAX. STROKES / MIN : | 120 | 150 | 150 |

| NET WEIGHT Kg | 900 | 1,200 | 1,700 |

| GROSS WEIGHT Kg. | 1,400 | 1,600 | 2,400 |

| CASE DIMENSIONS : | 2000 x 1100 x 1850(H) | 2400 x 1270 x 1930(H) | 3430 x 1400 x 1930(H) |

| Packaging Detail:sea worthy export packing |

| Delivery Detail:6 weeks |