ZHOUSHAN rubber screw barrel manufacturer

| Place of Origin:Zhejiang China (Mainland) | Brand Name:DONGXIANG | Model Number:DB0052 | Plating:Chrome |

| Type:Machining Parts | Material:38CrMoAIA | Certification:ISO 9001:2008 | Screw edge processing::bimetal spray-finishing |

| Amount::one set | Customize::Accept | OEM Production::Accept | Design::Can |

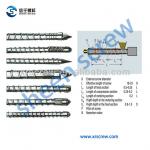

ZHOUSHAN rubber scew barrel manufacturer

1.Technical index

1 Φ120 barrel for pinned type extruder

2 Technical Specification

3 Hardness After Hardending&Tempering : HB240~280

4 Nitrided Hardness : HV950~1000

5 Nitrided Case Depth : 0.55~0.7mm

6 Nitrided Brittleness :Less Than Grade 1

7 Surface Roughness :Ra 0.4

8 Screw Straightness :0.015mm

9 Surface Chromium-Plating’s Hardness After Nitriding≥900HB

10 Chromium –plating Depth :0.05~0.10mm

11 Alloy Hardness : HRC55~62

12 Alloy Depth :1.5~2.0mm

2. Material&Processes

14 Quality 38CrMoALA

15 Qulity Duplex Stainless Steels

16 GH3#Steel

17 Quality Powder Metallurgy Raw Materials

18 Cold/Thermal Spray Hard Metal Process

19 Advanced nitriding Process

20 Corrosion & Abrasion Resistance Bimetal Spraying Process

21 Horniness screw (HTP1:abrasion HTP2:corrosion resistance,HTP3:abrasion and corrosion resistance)

3.the best-seller model information:

4.the photos of product :

5.workshop

6.we supply the screw and barrel to the following company:

We are biggest pinned screw barrel factory in China, have many coopertative parter all over the world. Such as: FranceMichelin,Japan Bridgestone,American RMS machinery,ChinaGuilin rubber institute, Shanghai Jinyuan, Yokohama Tire, Sumitomo Tire, Giti Tire, Cooper Chengshan Tire, Double Coin Holding LTD, Guizhou Tire Group, Triangle Group, Aeolus Tyre, etc .

7.the quailty of product:

1.Our base steel material: 38CrMoAla.

Bimetallic alloy material: Fe-based alloy and Ni-based alloy

2.Treatment of the bimetallic screw barrel:

Bimetallic Barrel/Cylinder: Centrifugal Casting (Inlay Alloy)

Bimetallic Screw: Plasma Alloy Coating Spraying

Depth of Bimetallic Layer: >2mm

Hardness of Bimetallic Layer: HRC55°-72°

3 The lead time of the screw barrel in within 30-35days after receive the first payment.

4 The team of payment: By T/T, deposit 30% in advance, the balance paid before shipment .

5 Guarantee: Nitrided screw barrel 1 years

Bimetallic screw barrel 2years

The life time of the screw barrel is depend on the raw material of your product.

8.the screw and barrel for application:

| Packaging Detail:wooden box meet export standard |

| Delivery Detail:35 days after receiving deposit |