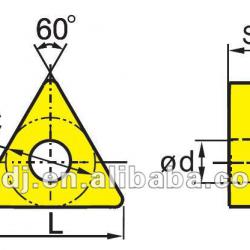

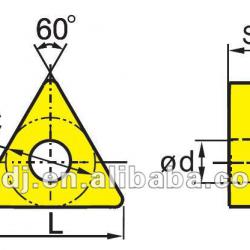

ZCC.CT TNMG160408 Tungsten carbide inserts

| Place of Origin:Hunan China (Mainland) | Brand Name:ZCC.CT | Model Number:TNMG160408 | Color:Yellow |

| Material:Tungsten Carbide | Package:Plastic box | Coating:MT-TiCN,thick layer of Al2O3 and TiN | MOQ:10 |

| Cut inside diameter:3.81mm | Blade thickness:4.76mm | Tools-tip arc:0.8degree | length:16.5mm |

| Inscribed circle diameter:9.525mm |

YBC151

The combination of substrate withexcellent wear resistance and coating made up of MT-TiCN,thick layer of Al2O3 and TiN; It’s suitable for finishing steel.

YBC251

The substrate with good toughness and high security on cutting edge, in optimal combination with coating made up of MT-TiCN,thick layer of Al2O3 and TiN; It’s suitable for semi-finishing steel.

YBC351

The substrate with high strength and resistance against plastic deformation, in combination with coating made up of MT-TiCN,thick layer of Al2O3 and TiN; It’s suitable for roughing steel.

YBM151

Subs t rate wi th spec ial s t ruc ture, i n combination with coating made up of TiCN, thin Al2O3 layer, TiN, with the capability of excellent resistance against diffusive wear and plastic deformation ,which is suitable for finishing, semi-finishing and roughing of stainless steel.

YBM251

Combination of substrate which with good toughness and strength and coating made up of TiCN, thin Al2O3 layer and TiN, the grade is suitable for semi-finishing and roughing stainless steel.

YBD151

The best combination of substrate with high wear resistance and coating made up of MT-Ti(CN),thick Al2O3 layer and TiN, which is suitable for finishing and semi-finishing cast iron materials.

YBD152

CVD coated grade, which is combination of hard substrate and coating (medium thick Al2O3 + thick TiCN), good flaking resistance. It’s suitable for turning cast iron at high speed, and light intermittent cutting can be supported even under moderate speed. It’s also suitable for milling cast iron.YBD

YBC252

Comprising of thick TiCN and thick Al2O3 coatings, the grade has high capability against plastic deformation and good hardness on cutting edge, and It’s preferred grade for machining steel from finishing to roughing. Under the same cutting conditions, the cutting speed can be improved more than 25% while life of tool can be 30% longer than old grade under the same cutting speed.

Excellent Performance:

1.Unique point design, with a sharp edge, cutting small resistance, reduce the props to vibrate

2. Blade repositioning precision is high, can with specially developed for cemented carbide tool rod matching, improve the tool's ant-vibration performance, further assure processing quality

3. Blade via special surface treatment, decrease cutting knife surface bonded in the former, the possibility of broken cutting good performance, and ensure the broken cutting and discharge, is more advantageous to improve the surface quality.

4. Adopts excellent performance synthetics, suitable for various processed materials of precision processing.

| Packaging Detail:10 pieces put into a plastic box |

| Delivery Detail:3-15 days |