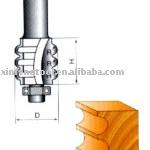

Woodworking Spindle Motor For CNC Router ,Air Cooled

1. Servo motor,Italy air cooling, 2. suit for all kinds of CNC machine, 3. used in wood working, milling and engraving - details see: https://www.machineto.com/woodworking-spindle-motor-for-cnc-router-air-cooled-10358074

| Place of Origin:Shandong China (Mainland) | Brand Name:MS | Model Number:1.5kw(all models you need) | Production name:Spindle motor |

| Usable range:CNC drilling,milling,grinding,engraving,cutting, | Certification:CCC, CE | Phase:Three-phase (optional) | Voltage:380V |

| Second-used:optional | Attentions:must be connected with FREQUENCE | | |

WelcometoVisit MS-spindles(all kinds of models)

| Payment & Samples |

| Payment Terms | L/C | T/T | | | |

| MOQ | 1 set | | | | |

| Sample Available | No free Sample, customer can purchase 1 set as sample |

| Packing & Delivery |

| Packing | carton | wooden case if it`s necessary |

| FOB Port | Qingdao or any others | | | | |

| Package Size | according to your model | | | | |

| Weight(Include Package) | according to your model | | | | |

| Warranty | a) half year against manufacturing defect for spindle |

| b) one year against manufacturing defect for other parts |

| c) offer lifetime consultation on problems occurred |

| Tips before using: for all spindles |

| 1 | The electric spindle and the frequency inverter shall be suitable with each other. The specifications and parameter settings of the inverter shall match the nominal parameters of the spindle, and it will burn the spindle if the settings are not correct. |

| 2 | Before using water-cooling spindle, it shall ensure that cooling cycle system works normally and the running under no cooling conditions is prohibited. The volume of cooling water is calculated as per 1 liter/kw, minute, the minimum flow of cooling water is not less than 5 liter/minute, cooling water pipe and the nozzle shall be connected reliably and there is no leakage. |

| 3 | The cooling liquid shall be clean and free of grease and the temperature shall be within 5-30°C. The cooling medium shall carry outforce cooling when the ambient temperature is higher than 30°C. The precision lathe requires the cooling liquid with a constant temperature of 20±2°C. |

| 4 | During storage and transport of the spindle, the status of high-speed grease inside the bearing will change. The user shall run it at a low speed first by starting from the lowest speed of the spindle for 30 minutes and then 20 minutes for every 3000 rounds; otherwise there will have abnormal sound, noise, heat and other phenomena, which will affect the bearing life if the spindle is started directly at a high speed. During long term storage, the spindle shall run (at low speed) for 15~30 minutes once a week at least. |

| 5 | Collet, nut and inner taper hole shall be washed clean when installing blades on the spindle in order to avoid any impact on the precision. The blade handle shall be inserted into the collet more than 15mm. |

| 6 | For daily machining, the spindle shall be warmed up, run for 15~20 minutes when the machining speed is reached and then performs precise machining. It is better to stop the spindle for two hours every day in order to recover its mechanical fatigue and prolong its life time. |

| 7 | No knocking the end cover of the spindle. No hammering the collet and blade head when removing blades. No shocking or colliding during transport, storage and using, especially the end of the spindle. |

| 8 | The spindle shall run in designated direction. |

| 9 | The spindle shall be installed and fixed according to the relevant drawings and instructions. |

| 10 | The temperature shall be within 22-25°C if water cooling machine is used. |

| 11 | The spindle adopts vapor lock and the gas source shall not be used until it has passed oil-water separator and dry filter. The air pressure is 0.2-0.25MPa and the filtering precision is 5μm, otherwise there will cause damages to the bearing. |

Our spindle is with high quality and great performance. We could supply manual reblading spindle , belt drive spindle and also ATC spindle. The power for the electric spindle is from 0.6KW to 12KW, diamet from 62MM to 150MM, joint of nose ER8 ER11 ER16 Er25 ER32 ER40. The spindle for our motor spindle, there is 12000RPM, 18000RPM, 24000RPM, 42000RPM, 60000RPM, will meet customers need. If you have inquiry about spindle, pls do not hesitate to contact us and send us your detailed requirement. We will glad to get your mail for motor spindle or other spindles.

| Model | Power | OD*Length | Collet | Frequence | Voltage | Speed |

| Water Cooling Spindle | | | | |

| MS-62A | 800W | 62*200mm | ER11 | 400Hz | 220V | 24000rpm |

| MS-65C | 800W | 65*205mm | ER11 | 400Hz | 220V | 24000rpm |

| MS-80A | 1500W | 80*185mm | ER11 | 400Hz | 220V | 24000rpm |

| MS-80B | 2200W | 80*205mm | ER20 | 400Hz | 220V/380V | 24000rpm |

| MS-80C | 2200W | 80*215mm | ER20 | 400Hz | 220V | 24000rpm |

| MS-80D | 1500W | 80*185mm | ER16 | 400Hz | 220V | 24000rpm |

| MS-80E | 1500W | 80*215mm | ER11 | 400Hz | 220V | 24000rpm |

| MS-80F | 1500W | 80*215mm | ER16 | 400Hz | 220V | 24000rpm |

| MS-80G | 2200W | 80*215mm | ER16 | 400Hz | 220V | 24000rpm |

| MS-80H | 2200W | 80*223mm | ER20 | 400Hz | 220V | 24000rpm |

| MS-M80A | 1500W | 80*237mm | ER16 | 400Hz | 220V | 24000rpm |

| MS-100A | 3000W | 100*252mm | ER20 | 400Hz | 220V/380V | 24000rpm |

| MS-100B | 2200W | 100*228mm | ER20 | 400Hz | 220V/380V | 24000rpm |

| MS-100C | 3000W | 100*271mm | ER20 | 400Hz | 220V/380V | 24000rpm |

| MS-105A | 3500W | 105*271mm | ER20 | 400Hz | 220V/380V | 24000rpm |

| MS-105B | 3500W | 105*252mm | ER20 | 400Hz | 220V/380V | 24000rpm |

| MS-125A | 4500W | 125*320mm | ER25 | 330Hz | 380V | 20000rpm |

| MS-125B | 4500W | 125*332mm | ER25 | 330Hz | 380V | 20000rpm |

| MS-M85A | 2200W | 85*288mm | ER20 | 400Hz | 380V | 24000rpm |

| MS-80J | 2200W | 80*230mm | ER20 | 400Hz | 220V | 24000rpm |

| MS-80K | 2200W | 80*225mm | ER20 | 400Hz | 220V | 24000rpm |

| MS-80L | 2200W | 80*232mm | ER20 | 400Hz | 220V | 12000rpm |

| Fans Cooling Spindle | | | | |

| MS-80A | 1500W | 80*220mm | ER11 | 400Hz | 220V | 24000rpm |

| MS-3.5KW | 3500W | 94*82*312 | ER25 | 300Hz | 380V | 18000rpm |

| MS-4.5KW | 4500W | 120*103*302 | ER32 | 300Hz | 380V | 18000rpm |

| MS-65A | 800W | 65*206mm | ER11 | 400Hz | 220V | 24000rpm |

Thank you for visiting, and Pls. send me email if you are interested in our products, we provide 24h service.

| Packaging Detail:standard case for exporting |

| Delivery Detail:7-10 working days |

Related Product for Woodworking Spindle Motor For CNC Router ,Air Cooled