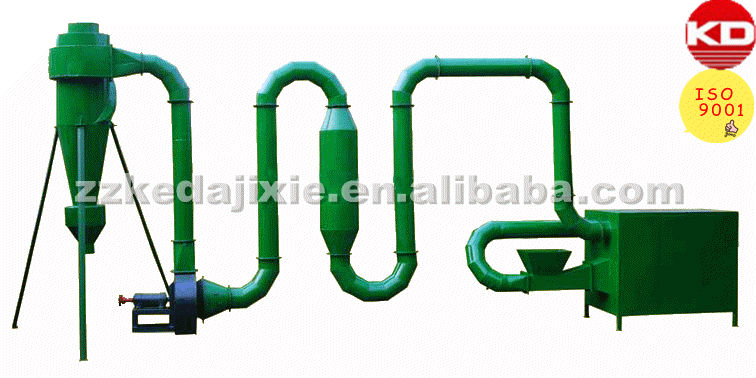

Wood Chips/Sawdust Air-Dryer Machine

| Condition:New | Type:Fluid Bed Drying Equipment | Place of Origin:Henan China (Mainland) | Brand Name:keda |

| Model Number:FG/QG | Voltage:220/380/440 | Power(W):7000-150000 | Dimension(L*W*H):none |

| Weight:none | Certification:ISO9001 | Warranty:one year | After-sales Service Provided:Engineers available to service machinery overseas |

| paint:at your requirement |

Fodder Fluid-bed Drying Machine with High Efficient

1.Brief:

The air dryer use a high-speed flow of the hot gas stream so that the wet starch suspended therein, and dried in the air flow process.Having a high heat transfer coefficient, large heat transfer area, short drying time.Air drying, also known as "instant dry" This method is the heating medium and be dried solid particles directly contact, and to be dried solid particles suspended in the fluid, and thus the two-phase have large contact area to enhance the heat and mass transfer process, widely useddry bulk materials.

2.Material:

A3 steel, stainless steel, aluminium alloys, titanium alloys

3.Heating way:

Air drying equipment has greater adaptability in the heating mode selection, steam, electricity, stove heating, the user can choose in accordance with the conditions of the area, but also according to the choice of materials heatproof temperature (or hot air temperature): ≤ 150 ° C may make use of the steam heating; ≤ 200 °C the electric heating (or steam heating, electricity compensation or oil heating); ≤ 300 ° C, the coal-fired hot air furnace; ≤ 600 ° C, oil-fired hot air furnace.

4.type and principle of work:

(1)Cyclonic air dryer

Drying material particles tangentially into the cyclone dryer which is driven by hot air , rotational motion along the hot wall, so that the material particles in the suspension rotary motion state and drying. The wall can be set as required steam jacket. The drying process is greatly enhanced. In addition, due to the impact of particles with the wall material has been crushed. The gas-solid contact area is increased, but also to enhance the drying process.Hydrophobic, not afraid of crushing heat-sensitive bulk granular materials is particularly applicable. But the high water content, viscosity, low melting point, easy to sublimate explosion, easy to produce static effect of the material is not applicable.

(2)Straight pipe air dryer

The wet material is fed into the upright tube, the air through the blower blown into the finned heater, blown into the upright tube after being heated to a certain temperature .The rate determined by the size and density of the wet granules, within the tube is generally greater than the settling velocity of the particles (approximately 10 to 20m / sec). The dried particles are send by strong airflow to the two parallel cyclone separation, and then sent by the screw conveyor, exhaust released by the bag filter. Due to the short residence time, for certain products often requires the use of two-stage or multi-stage series process.

(3)Pulse air dryer

When the drying operation, the diameters alternately reduced or expanded to permit the flow of gas and particles not isokinetic flow, the relative velocity and the heat transfer area between the gas stream and the particles are larger, so as to enhance the heat and mass transfer rate. In addition, the air velocity in the expanding tube greatly decreased, there is a corresponding increase in the drying time.

5.Application:

sawdust,wood chips,fish meal, sugar, starch, glucose, distiller's grain, feed, Gluten, plastic resin, coal, dyes

6.Features:

Large dry strength, saving investment, processing is the largest, by evaporation of water capacity from 50kg/h-1500kg/h ,small volume of equipment, high degree of automation, high product quality, air drying materials all in the pipeline, drying time extremely short (O.5-2 seconds), so you can automate, the product is not in contact with the outside world, pollution-free, good quality.

7.QG main technical parameter:

| Item | Evaporated capacity(kg/h) | Total power(kw) | Occupied area(m2) | Height(m) |

| Qg50 | 50 | 7 | 20 | 9 |

| Qg100 | 100 | 13 | 32 | 11 |

| Qg200 | 200 | 21 | 40 | 11 |

| Qg250 | 250 | 24 | 64 | 13 |

| Qg500 | 500 | 43 | 96 | 13 |

| Qg1000 | 1000 | 100 | 120 | 15 |

| Qg1500 | 1500 | 150 | 200 | 16 |

8.FG main technical parameter:

| Model | Evaporated capacity(kg/h) | Power(kw) | Occupied area(m2) | Heat rate(%) |

| FG0.25 | 113 | 11 | 3.5×2.5 | >80 |

| FG0.5 | 225 | 18.5 | 7×5 | >80 |

| FG0.9 | 450 | 30 | 7×6.5 | >80 |

| FG1.5 | 675 | 50 | 8×7 | >80 |

| FG2.0 | 900 | 75 | 11×7 | >80 |

| FG2.5 | 1125 | 90 | 12×8 | >80 |

| FG3.0 | 1150 | 110 | 14×10 | >80 |

| FG3.5 | 1491 | 110 | 14×10 | >80 |

9.the daily maintenance of the mechanical:

(1)Before going to work every day to check the automatic drain valve on the pre-filter.

(2)Check for tower and boost action is normal.

(3)Check the operating conditions, the import of pressure, inlet temperature and air flow.

(4)Check the moisture indicator, blue for dry, red for wet.

(5)Check the muffler fouling, regeneration tower rushed back pressure is too large, which means that the need to replace the muffler.

(6)Check the pre-filter and post-filter pressure drop, if the pressure drop of more than 0.5 bar, replace the filter.

10.Notes for use:

(1)Before put into use the lubrication parts for lubrication.

(2)Dryer is put into use, must be properly adjusted, the supply of sufficiently high quality more than 6 atm (gauge pressure) steam dryer in order to make full competence.

(3)Note that when using start-stop sequence. Before the commissioning of the first to open the steam valve, close the regulating valve, and then start the fan. Shutdown in reverse order, first stop the feeder to be seen rows of net material and then stop the fan and close the steam valve.

(4)The adjustment operation scraper centrifuge, the moisture of the wet material is low andstable.Feeders feeding evenly.

(5)Pay attention to fire safety, the dust around the dryer promptly cleaned. Is strictly prohibited in the workshop smoking. Welding repairs must be shut down and fire prevention treatment.

| Packaging Detail:standard container or at your requirement |

| Delivery Detail:within 15 days after the down payment |