vacuum oil purifier,Professional Machine! manufacturers of petroleum refinery equipment

| Condition:New | Flow:20.0KW | Working Pressure:normal/negative pressure | Place of Origin:China (Mainland) |

| Brand Name:Beston | Model Number:ZL-2 | Usage:manufacturers of petroleum refinery equipment | Voltage:380V |

| Power(W):120KW/H | Dimension(L*W*H):3600*6000*2 | Weight:120MT | Certification:CE&ISO |

| After-sales Service Provided:Engineers available to service machinery overseas | Raw material:crude oil, waste,waste engine oil | Reactor Materail:Q245R or Q345R Boiler Steel Plate | Reactor Size:D2800 x L6200mm |

| Working Form:Continuous | Structural form:vertical band tower | Heating form:Tubular Heating/Hot air system | Reactor Rotatable Speed:0.4-0.8turn/minute |

| 24 Hours Capacity:50 T | Average Extration Rate:50% | Service Life:5-8Years |

vacuum oil purifier,Professional Machine! manufacturers of petroleum refinery equipment

3D Drawing

Flow Chart

Technical Sepcification

| Type | JL-1 | JL-2 | JL-3 | JL-4 | JL-5 | |

| Raw material | Waste Oil, Raw oil, Waste Engine Oil, Waste Raw Oil, Waste Washing Oil | |||||

| Structural form | Vertical belt tower | |||||

| Size of reactor | (1600*4400)mm | (2200*5100)mm | (3000*5000)mm | (3600*6000)mm*2 | (3600*6000)mm*2 | |

| 24-hour Capacity | 6T | 10T | 25T | 50T | 100T | |

| Rate of oil yield | 70%-80% | 70%-80% | 90% | 90% | 90% | |

| Power | 20.0 KW | 20.0 KW | 38.0 KW | 50.0 KW | 80.0 KW | |

| Working form | Intermittentoperation | Intermittent operation | Continuous operation | Continuous operation | Continuous operation | |

| Heating mode | Hot air | Hot air | Hot air | Tubular heater | Tubular heater | |

| Consumption of cooling water (T/h) | 9 | 9 | 18 | 40 | 100 | |

| Production period | 20 days | 20 days | 40 days | 60 days | 60 days | |

| Mode of cooling | Water cooling | |||||

| Material of reactor | Q245R/Q345R boiler plate | |||||

| Heating material | Coal, charcoal, fuel gas, fuel oil | |||||

| Thickness of reactor | 16mm | |||||

| Rotate speed of reactor | 0.4-0.8 turn/minute | |||||

| Operating pressure | Normal and negative pressure | |||||

| Mounting means | Having base | |||||

| Noise dB(A) | ≤85 | |||||

Main Features

Main Technical Characteristics

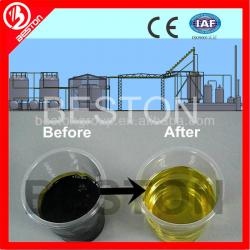

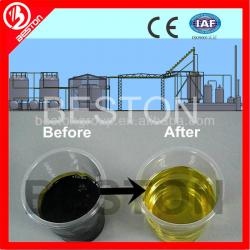

1. The key unit adopts vacuum catalytic cracking technology and chemical extraction technology.

2. There is complete equipment equipped for environmental protection, e.g. waste gas burner and flue gas dust collecting room.

3. Adopt simple chemical method; eliminate the colour and peculiar smell of products.

4. The output capacity of pure raw oil is less than 80%.

5. The design of unit is reasonable, the manufacturing process is advanced, the operation is highly automatic and the safety facilities are complete.

6. Have multiple purposes.

Domestic initiation

a. The complete set of unit produces no smoke and smell with favourable effects of environmental protection.

b. The pressure release device operates through water circulation, which greatly improves the security of the system.

c. The release of pressure during the production dramatically increases the output within certain time and meanwhile improves the quality of oil.

d. The heating system adopts hot air heating technology, which improves the safety performance of production and heating efficiency.

e. High efficiency fuel gas heating system. When the heated gas reaches 150 during refining, a large amount of gas will be generated: through methane to butane, which cannot be liquefied under normal temperature. A large quantity of energy will be generated after these gases fully burn within a specially designed gas burner. Then energy will be saved greatly.

The total production consumptionZL-2

1. Power: 120kw/hour in total (but it is not every device start at the same time).

2. Cooling circuit water: 50m3/hour in total (the water can be recirculated and the more the water flow, the better the cooling down).

3. Fuel for heating:

30——40KGcoal for processing one ton raw oil for average.

4. Space for machine:3000----3500(the smallest square ).

Advantage:

1.Unique technology for increasing the oil output (the oil yield is not less than 90% when the water by extraction is less than 5%);

2.Reducing the fuel consumption (20 kg diesel for each ton of wast oil) and preventing coked.

durning the processing with high tech pyrolysis oil fefining 3.we are good at reducing the sulfur, cloud point and color of the oil, which can be provided separately with additional cost.

Company Pomise:

There is complete aftersale service for series of unit from out company. The warranty period of the main part of unit is 1 year, which completely eliminates customers’ worries.

Real Pictures of manufacturers of petroleum refinery equipment

General Production

vacuum oil purifier,Professional Machine! manufacturers of petroleum refinery equipmentWelcome to contact us if you need more information.

| Packaging Detail:Standard Export Packing of manufacturers of petroleum refinery equipment |

| Delivery Detail:30-45 Working Days of manufacturers of petroleum refinery |