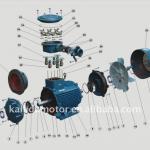

Three-phase step motor vibration sources

| Place of Origin:Henan China (Mainland) | Brand Name:TongXin | Model Number:TZX | Type:Motor Actuator |

Three-phase step motor vibration sources - Maintenance Manual

I. Overview

Source of vibration set of three-phase asynchronous motor power source and the source of vibration as a whole, is a universal energy-efficient source of vibration, small size, excitation force, structure, and reliable to use and easy maintenance

This series of products are widely used in mining, coal, electricity, chemical industry, food processing, metallurgy, casting, building materials, light industry, medicine and other industries. Is to achieve powder, granular, lump and other granular materials mechanized screening, conveying, crushing, filling, anti-clogging the ideal excitation source.

The machine can be used stand-alone, multi-machine can also be used in combination.

Electrical conditions of use

This series of motors to meet the following conditions, be able to continuously output rated exciting force.

1) vibration acceleration: no more than 7g (g: acceleration due to gravity)

(2) Environmental temperature: not more than 40

(3) above sea level: not exceed 1000m

(4) Power frequency: 50HZ, 60HZ

(5) Voltage 380V, 380/660V

(6) temperature rise: less than 80K (resistance method)

, pre-installation preparation

(1) Check motor nameplate is in line with the requirements.

(2) a 500 megger insulation resistance measurement, and its value should not be less than 0.5 megohm, otherwise, the stator windings should be dried, drying temperature should not exceed 120 .

(3) Check the motor of all fasteners, to guard against loosening.

(4) Check the motor surface for damage, deformation.

, installation and adjustment of

(1) The motor should be fastened on the mounting surface, install the surface must be smooth, flat.

(2) the level of motor can be installed, you can also tilt to install.

(3) Electrical outlet with four-core rubber cable, the standard electrical specifications shown in Table used to qualify the cable source does not allow emergency pack, cables and vibration body should be reliably fixed.

(4) The motor should have a reliable grounding, wiring box with ground installations and signs can also be used at the end of grounding pin fastening bolts.

(5) exciting force adjustments

Motor factory, horizontal vibrating motor excitation force at the maximum position, if the exciting force is too large, the user can be removed at both ends of shield, simultaneous adjustment at both ends of adjustable eccentric block and fixed angle between the eccentric block, so that excitation force meet the requirement, the greater the angle, the smaller the excitation force, pay attention to every regulation must be the angle between the motor at both ends of the size of the same scale, and the side ipsilateral motor. Vertical vibrating motor to rely on conditioning with weights up and down the weight and the angle between the two eccentric block to achieve the device the best results.

, use and maintenance of

(1) The machine shall be equipped with electrical protection device.

(2) This machine is running early, check every day for at least a foot to bolt to prevent loosening.

(3) When the motor rotation direction does not meet requirements, you can adjust the power supply phase sequence.

(4) The motor should ensure that well-oiled every 720 hours to run to add three # 2 molybdenum disulfide lithium grease once, by adding the amount of capacity for the bearing cavity 1/3-2/3.

(5) The machine is running 2,000 hours accumulated, it should check the bearings, if serious injury should be replaced immediately.

(6) This aircraft parked or garaged when used again after a long time, insulation resistance should be measured with 500V megger measurement, should be greater than 0.5 megohm.

(7) motor running Do not remove protective cover, due to conservation of the removal of the protective cover on the request and fashion so as to prevent water and dust into the motor internally. Otherwise easily lead to bearing damage in a short time winding.

, common fault handling:

| Serial Failure | Possible Cause | Disposal route |

| power supply connected motor does not start after the | 1, stator windings and white short-circuit, the stator winding ground blocking road 2, stator winding connection error 3, load, or blocked rotor | 1, check the open circuit, short circuit grounding parts and repair. 2, check the winding wire, and correct 3, reducing the load, to remove the obstacles |

| Motor temperature too high or smoke | 1, overload 2, winding short-circuit 3, winding connection error 4, winding inter-turn short circuit or grounding 5, rotor broken bars 6-phase stator and rotor rub | 1, reducing the load or replace motor 2, repair short-circuit position 3, check the winding wire, and correct 4, to identify trouble spots and fix 5, the replacement rotor 6, measuring motor air gap, inspection and bearing wear, etc. to repair it. |

| Bearing overheating | 1, bearing wear or quality problems 2, bearing grease too much or too little, the models are incorrect or poor quality 3, bearing inner ring and shaft with loose or too tight 4, bearing outer ring and the cover too loose or too tight co-ordination 5, cover with the bearing assembly within the cover poor quality | 1, the replacement bearings 2, adjust the grease 3, too loose, it would be a lap weld metal shaft plus reprocessing, tight bearing file when re-processing. 4, too loose, can be intercalated end of the bearing chamber cover an expanded set of tight inlaid bearing chamber when the re-processing 5, removed and then installed, so that uniform bearing force |

| Motor shell Charged | 1, grounding bad 2, winding insulation damage 3, winding damp 4, wiring board is damaged, or too much dust and dirt | 1, find out the reasons and fix 2, repair insulation, and to make Impregnating dried 3, dry handling or Impregnating Dry 4, replacing wiring board, clean up dust and dirt |

| Stent leg fracture | 1, anchor bolts do not tighten 2, the installation is not enough flat plane | 1, tighten bolts 2, re-install the graphic processing |

transport and storage of

When the motor in the transport and storage of non-inverted, non-accumulation, prevent damp.

| Packaging Detail:in paper carton |

| Delivery Detail:7days |