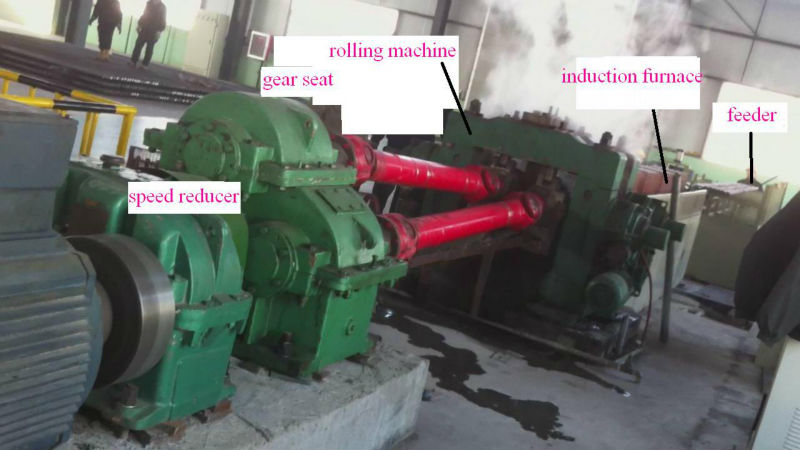

skew rolling mill for stell ball

| Place of Origin:Henan China (Mainland) | Brand Name:Anyang | Model Number:XZJ | Diameter:20 |

Steel milling ball: diameter 20-130mm

Bearing steel ball and roller: diameter 20-60mm

Anode phosphorus copper ball: diameter 25-45mm

Aluminum ball and shot put: diameter 5-30mm

Complicated parts: Gearbox thermodynamic, four league gear, Hand electric drill subject

Anchor: diameter 20-40mm

specification:

Type | SR-20 | SR-30 | SR-40 | SR-50 | SR-60 | SR-80 | SR-100 | SR-120 |

Diameter of ball milled (mm) | 15--20 | 20--30 | 30--40 | 35--50 | 40--60 | 60--80 | 70--100 | 100-120 |

Max diameter of rolling mill (mm) | 140 | 220 | 260 | 300 | 340 | 450 | 600 | 690 |

Rotating speed of rolling mill (r/min) | 65 | 110 | 80 | 72 | 72 | 64 | 50 | 40 |

Max obliquity of rolling mill (degree) | 0--5 | 0--6 | 0--6 | 0--8 | 0--6 | 0--8 | 0--7 | 0--7 |

Motor power (KW) | 30 | 40 | 90 | 130 | 180 | 450 | 650 | 1000 |

Machine weight (ton) | 2 | 3 | 8 | 10 | 20 | 30 | 50 | 110 |

Overall size (L×W×H) (mm) | 2600×1700×500 | 3200×1200×1000 | 5200×1400×1000 | 6500×1500×1000 | 7400×2000×1400 | 9600×2600×2200 | 1200×3000×2800 | 1400 |

1. Theessenceofpig ironcastingball,addinga large quantity of(13-28%)chromium,toachievetherequirementsofthemillingball.

3. Highenergy consumption, pollution,laborintensity, low labor productivity.

5. Highcost of raw materials,highwage costs,theballespeciallyF50mm,thecostishigher.

1. Alltheadvantagesofthehot-rolledsteel ballwith asteelqualitybyheat treatmentaftermillingball.

2. Highproduction efficiency,large output,highrollingballproductionmechanization and automation,production processeswithoutmanual operation.

3. Stablequality,goodhardness,goodhardenability,densemicrostructure,fine grain,good abrasion resistance,the abrasion of hot-rolled steel ball is half of casting ball,impact toughnessupto12-35J/cm2,crushingrate of is less than1%.

4. Lowenergy consumption, no pollution,lowlabor intensity,lowerproduction costs,in the long run,casting ballwill inevitablybe replaced by rollingballand steel ball.

| Packaging Detail:wooden case |

| Delivery Detail:with in 120 days after get the down paymen |