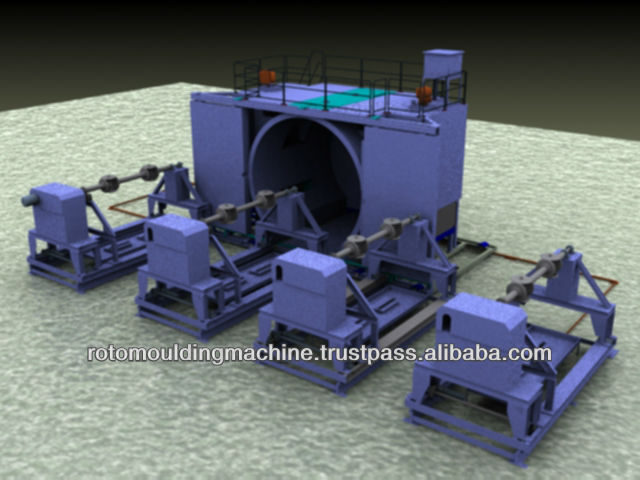

SHUTTLE ROTO MOLDING MACHINE

| Place of Origin:Goa India | Brand Name:SARMI | Model Number:MULTI ARM MULTI AXIS MACHINE | Condition:New |

| After-sales Service Provided:Engineers available to service machinery overseas |

SHUTTLE ROTO MOLDING MACHINE

Sr. | Description | Prices – Ex works, |

1 | Multi Axis Two Arm Machine As per attached technical specification | USD 78,000 |

TECHNICAL SPECIFICATION

ANNEXURE V – B (4.01A)

TYPE OF MACHINE | Multi Arm Multi Axis M/c. With Two Arm |

Swing Dia. Of the Oven | 4.0 Meter (4000 mm) |

Max. Moulding Capacity | 3000 mm ( Spherical ) |

Number of Arms | Two |

Arm Specification | Arm 1: Type of Arm : Offset Arm Assembly: Supported at both the ends. Max. Mould Dimensions(1):3000 mm Spherical Major Drive: 10 H.P. DC Variable Driven Minor Drive : 5 H.P. DC Variable Driven Traveling: Motorized |

Arm Specification | Arm 2: Type of Arm : Straight Arm Assembly: Supported at both the ends. Max. Mould Dimensions(4):1250 Ø x 1200mm L Major Drive: 3.0 H.P. DC Variable Driven Minor Drive : 2.0 H.P. DC Variable Driven Traveling: Motorized |

Oven Specification | Size(Inside): 4200 mm x 4200 mm x 4800 mm Movable / Stationary :Stationary Temperature Sensing element Doors : Motorized Insulation : 150 MM THK – ROCKWOOL Inside Color : Heat Resistive – Silver Second Charge Provision : Incorporated |

Heating of the Oven | Burner : Two – Auto ignited with Sequence Controls. Air Re-circulating Blowers : Four Nos. |

Cooling Station | No. of Cooling Fans : Two |

Mounting of Moulds | - Easy mould mounting with bolting system. - Simple Mould Mounting system without any additional cost for the mould carriers. |

Control Panel | Controls of Arms: - Major and Minor drive on/off, RPM setting: Auto - Reverse Forward, Digital Ampere meter, Adjustable Controls of Oven / Burner- Digital Temperature Controller - Blower – Switches - Burner Switches - Emergency Stop Button |

Power requirement | Major and Minor Drive of Sh. 1 = 15 HP Major and Minor Drive of Sh. 2 = 5 HP Air re-circulating Blower = 10 HP Burner – 0.25 = 0.5 HP Fans (01 No.) 0.79 x 2 = 2.0 HP |

Space required | 12000 x 7000 x 8000 Meter(LxWxH) |

| Packaging Detail:WOODEN PALLET PACKING |

| Delivery Detail:50 DAYS |