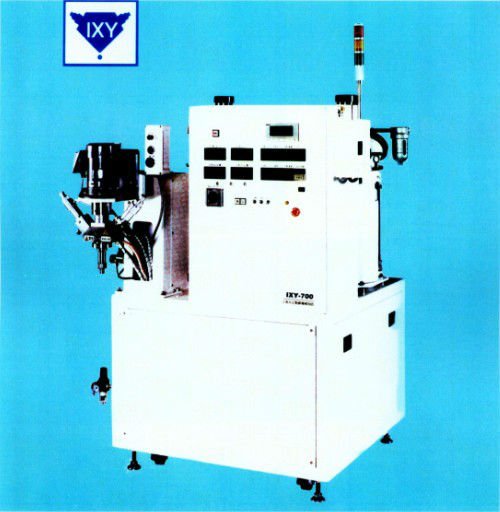

MOST Advanced Glue machine - Japen Tech

| Type:Gluing Machine | Condition:New | Application:Machinery & Hardware | Packaging Type:Other |

| Packaging Material:glue | Automatic Grade:Automatic | Driven Type:Electric | Place of Origin:Shanghai China (Mainland) |

| Brand Name:Spotgum | Model Number:IXY | Category:Gluing Machine |

Facilities for Tow-liquid Automatically-mixed Quantitative

Glue-pouring Machines with Small-scale

IX-300/IX500/IX600/IX700

Features of Glue machine :

precise ratio measurement and quantification dispensing,mixing rightly,and simple operation

Advantages:

dspensing quickly *no waste*precise gum exudation*working in order*on bad products and products and difficult fatigue.

General:

the machine,a fixed quantification dispensing machine with automatic mixture for two-liquid resinous dispensing,is suitable for connecting,bonding and mould-casting of all kinds of electrical parts,medical devices,automobile parts and components,etc.It can conduct automatic ratio measurement for such tow-liquid resins as ring-gas resins,polyurethane,silicon and polyester resin, and (time dispensing continuously)volume of dispensing is determined by using the timer, but it is a high-performance dispenser,suitable most for dispensing continuously of polyester resins.

Strong point:the machine uses a kind of high-precision valves to measure of resins and the main agent and hardener resins are circulating, but compared with the general approach,volume of dispensing for mixing ratio of main agent and hardener is correct and stability.

Main function:

1.Dispensing-valeDepartment:The company uses an unique dispensing valve to prevent liquor from dropping,and thus the stopping tangent is superior after dispensing and mixing resins are conducted during the moment of dispensing and pre-dispensing. In addition,dispensing valves can adjust spitting-out volume of dispensing they need.

2.Mixed Department: It is carried out compulsorily by electric motors or motors,a completely mixed method.Therefore,mixing resins completely with great mixing ratio and viscosity difference,it can spit out mixing ratio of resins quantitatively as materials,which is conducted both continuously and intermittently,especially for a small amount of (continuously) spitting-out.

3.Department of self-cleaning skills:Cleaning is automatically carried out through mixture of solvent and air ,and when the selection switch is put on the cleaning position and your foot presses it,cleaning automatically is conducted within the life time suitable for used resins,in order to prevent resins in the mixer from gelling.

4.Department of Raw Liquid Storage Tank:Standard raw material storage tanks from our company include 3L.5L.15L.20L.40L.60L.80L.and 100L.In special specifications,the main agent and hardener use the mixer’s raw liquid storage tanks. In addition, storage tanks,hoses,switches in the mixer and so on are heated by heaters.

5.Department of adjustment on spitting-out volume of dispensing from valves:The spitting-out valve of dispensing in the machine can automatically measure the spitting-out contents at a certain ratio.and in the operating panel,the discharged contents from main agent and hardener can be freely adjusted with very simple operation.

6.Department of pressure in the operating panel:Pressure gauge in the operating panel is to check abnormal phenomena on the spitting-out volume of resins.When they occur,there will be an alarm sounding or it is automatically shut down.

7.Department of alarm-resetting function:The resetting switches with alarm are set in the operating panel,and if there are abnormal situations of all parts,they will be shown or there is an alarm sounding.

8.Heaters of all departments.

9.Spitting-out device of time discharge.

10.Alarm.

11.The power light.

12.Schedule time.(Special specification)

13.Switches of adjustment of discharging contents from main agent and hardener.

14.Swutches preparing for running.

15.Switches of mixers in the main agent and hardener.

16.Resetting.

17.The power switch.

18.Air inlet.

Usage:1. Mould-casting of exoside resins of maggnetic heads,dispensing,exoside resins,components and shells.

2.Casting package for exoside resins of IC (integrated circuit)backplanes,dispensing,integrated circuit boards,castingpackage of Glue machine.

3.Mould-casting of exoside resins of sensors (sensitive components),dispensing and exoside resins.

4.Two-liquid exoside resins.

5.Mould-casting of exoside resins of semiconductors,dispensing,exoside resins and shells.

6.Mould-casting of exoside resins for thermo-sensitive switches of fan(motor)motors and dispensing.

Quantitative coating,injection,filling,sealing,dripping

AUTO.SPENSER LD SERIES

Mixed Spitting-out Machine or Lnjection Machine for Precise Tow-liquid Resinous Adhesives

they are sophisticated quantitative spitting-out facilities developed for one-liquid resins (exoside resins,silicone,instant adhesives and so on)or liquid (oil,grease,etc.).

Situations suitable for dispensing machnes:

A Computers, printers, keyboards, watches, clocks, pens, SMT.LED.LCD. semiconductors, medical equipment, catheters, headphones, eye-bell frames, drugs, plates, toys, cars, relays, speakers, connectors, radios, generators, TV, home appliances, batteries, golf heads, coils, switches, bearing,mesuring tools, equipment, light texture, cameras, knives, capacitors, motors, transformers, power-concentrating batteries, high-energy frequency controllers of flame lighters used for automobiles, electronic equipment, continuous spraying paint with facilities of the whole plant on batteries, non-inductive plastic film capacitors, thermo-sensitive switches, voltage interchangers for switched power source DC, electronic equipment, continuous spraying paint with facilities of whole plant on batteries, non-inductive plastic film capacitors, thermo-sensitive switches, voltage interchangers for switched power source DC, electronic key-phone, VCR production of auto filtering device ( instant adhesive), electrical products, vacuum circuit breakers, ornaments of pedometers, control apparatus of motor’s starting, switchboards, chemicals, synthetic resins, electronic music box and electronic stabilizers.

Advantages of Dispensing System:

B. 1-1 Dispensing quickly

1-2 No waste

1-3 Precise gum exudation

1-4 Working in order

1-5 No bad products

1-6 Difficult fatigue

Great decrease of cost for the dispensing system:

C.If your productivity can be increased by several times,you certainly can reduce the cost. If only to avoid the inconsistent situation of gum exudation, you can reduce the cost by decreasing non-performingrate. If only to avoid working messily and material waste,you can reduce costs.If it is not easy for workers to be fatigued,your productivity will be increased.

IXY-300 STYLE IXY-600 STYLE

Precise ratio measurement and quantification dispensing, mixing rightly, and simple operation

Situations suitable for dispensing machines:IC,LED,SSR,relays,motors,magnetic heads,switches,fans,backplanes,cosmetics, foods,batteries,computers,clocks,inductors,modules,capacitors,bearings,microphone,speakers,transformers,connectors,solenoid valves,etc.

(proper use of the machine).as seen in the following table

Power Source | Voltage AC85V~130V (Specified Voltage and Power Source Storageed Inside) | |

Power Consumption 16W | ||

| Mode of Power’s Control of Circuit | (Micro-computer)Electronic Control) | |

External Inputting Power | Inputting power by the short-wave (inputting power by non-contacting voltage) | Inputting power time of over 200mesc |

| Inputting power by the external (inputting power by non-contacting voltage) | ||

| Outputting power by contact points of external signal | Launching completion time 200mesc Outputting power by non-contacting voltage | |

| Compressed air | Common Standard 4kgf/cm2~5kgf/cm2 | |

| hydraulic adjustment | 0.2~4kgf/cm2 | |

| Spitting-out time | 0.02~99.99secend | |

| Spitting-out forms | Tow forms:time spitting-out and | |

| Outside Measurement | 180mm(W)*180mm(D)*68mm(H) | |

| Weight | 2KG | |

| Standard Equipment | Power Source Symbols of (between)Short-wave Inches | |

Products are follows:

-UV hardening Liquid coating

-Special liquid coating for base-plates

-Two-liquid mixed small-scale spitting-out

-Three-liquid Automatically mixed spitting-out

-Two-liquid mixing injection

-Moisture-proofing,electro-insulating coating paint:

-Assembly equipment of electronic products

-Injecting assembly hardening production lines

-Vacuum automatic adhesive combination

-Gum of exoside resins

-Foaming machine

| Packaging Detail:panel |

| Delivery Detail:in 15 days after the confirmation of the order |