magnetic sputtering coating machine

| Condition:New | Type:Coating Production Line,vacuum coating line | Substrate:Steel | Coating:Vacuum Coating |

| Place of Origin:Shandong China (Mainland) | Brand Name:LKBT | Model Number:DCLD--900 | Voltage:380 V |

| Power(W):45 KW | Dimension(L*W*H):900*1100 | Weight:3000 KG | Certification:TUV |

| Warranty:one year | After-sales Service Provided:Engineers available to service machinery overseas | Specification:Customized Definition | working methods:vacuum coating line |

| working gas:N2 or O2 Ar | substrade:steel | color:golden,silvery,black,rainbow color,rose color etc. | guarantee period:1 year |

| delivery time:50-60 days | apperance type:vertical single door |

Ms Laurie Skype:Laurie7816 Tel:86-13465501220 QQ/Wechat:554617049

Detailed Product Description

Technical parameter:

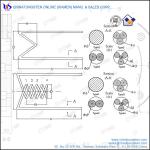

Mode Dimension | LH-800 | LH-1100 | LH-1250 | LH-1600 | LH-1800 |

| 800*1000mm | 1100*1000mm | 1250*1500mm | 1600*1800mm | 1800*1800mm | |

| Maily application | Metal decorative coating and Ceramic decorative coating | ||||

| Coating mode and main confirguration | Eight multi-arc targets | Ten multi-arc targets | Twelve multi-arc targets | Twenty multi-arc targets | Twenty two multi-arc targets |

| Power source | Electric-arc power, Filament power, | ||||

| Process gas control | Mass flowmeter + Electromagnetic ceramic valve | ||||

| Vacuum chamber structure | Vertical side opening door, pump system postposition, double water cooling | ||||

| Vacuum system | Molecule pump +Roots pump +Mechanical pump(8.0*10-5Pa) Diffusion pump +Roots pump +Mechanical pump(8.0*10-4Pa) | ||||

| Workpiece baking temperature | Normal temperature to 350 centi-degree PID control, radiation heating. | ||||

| Workpiece motion mode | Public rotation Frequency control: 0-20 rotation per minute | ||||

| Measure mode | Number display composite vacuum gauge: from atmosphere to 1.0*10-5Pa | ||||

| Control mode | Manual/Automatic/PC/PLC + HMI/PC four choice of control mode | ||||

| Remark | We can design the dimension of the equipment according to customers special technique requirement. | ||||

2 The vaporized metal molecule deposit on the substrates, to gain the smooth film as well as high reflectivity. Thus the surface of the items can be decorated and beautified.

3 Characteristic: reasonable structure, even film, good-quality film forming, quick pumping speed, the cycle of short, high efficiency and easy operation, low energy consumption and performance advantages of stability.

4 Coating color: gold, silver, red, blue, green, purple, multi color, and so on.

| Packaging Detail:standard packing |

| Delivery Detail:50--60 days after the deposit |