lowest price!!! rice bran extraction machinery with CE

| Condition:New | Usage:rice bran | Type:oil extraction | Automatic Grade:Automatic |

| Production Capacity:20tons per hour | Place of Origin:Henan China (Mainland) | Brand Name:shuguang | Model Number:SH |

| Voltage:380V | Power(W):15kwh/t | Dimension(L*W*H):20m*15m*10m | Weight:40tons |

| Certification:CE | After-sales Service Provided:Engineers available to service machinery overseas | worker:2-3 workers | plant area:1000-5000square meters |

| power:380V-50HZ | capacity:200t/d | Equipment size:20m*15m*10m | raw material:rice bran |

| Pressure:0.8MP | Machine Type:farm machine | oil class:first class | warranty period:1year |

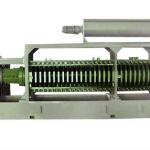

rice bran extraction machinery

I.Flow Chart

Craft flow for rice bran expansion workshop

Crude rice bran → cleaning → softening → expanding → drying → to extraction workshop

Craft flow for rice bran extraction workshop

solvent steam

↓ ↓

extraction → mixed oil → evaporation → steam-stripping → crude oil

II.Sunflower oil extraction machine Function:

Leaching system is an oil extraction through soaking or spraying pre-pressed cake by a certain organic solvent. The principle of this part is the different solubility of

solvent.

III.Soyabean oil extraction machine Main parts:

1. Solvent pumps: continuously spray solvent to the rotary-type extractor

2. Roary extractor: Spray and soak the pre-pressed cake with solvent so that oil fats can be

diss-olved in solvent (form miscella). After processing, you can get wet meal and miscella (mixed oil).

3. DTDC: usd to separate the solvent from the wet meal.

4. Miscella tank 1st: pump the miscella (oil with solvent) in to the miscella 1st , then add saline

water to it. The phospholipid in the miscella will react with the saline water, at last the reactant

precipitate, reaching the goal of purifying.

5. Miscella tank 2nd: the purified miscella will be pumped into it.

6. Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be

discharged to condenser for recycling.

7. Condensers: used to cooling the solvent gas separated from the wet meal and miscella for

recycling.

IV.Soyabean oil extraction machine Parameters:

| Residual oil in meal | ≤ 1% |

| Solvent consumption | ≤ 2Kg/T (No.6 solvent oil) |

| Crude oil moisture and volatile matter | ≤ 0.30% |

| Power consumption | ≤ 15KWh/T |

| Steam consumption | ≤ 280KG/T (0.8MPa) |

| Finished meal moisture | ≤ 13% (adjustable) |

| Residual solvent in finished meal | ≤ 300PPM (qualified detonated experiment) |

V.Soyabean oil extraction machine Advantages:

1. High oil yield , obvious economic benefit .

2. 1% Residual oil rate in the dry meal .

3. Improving the quality of the meal .

4. Low processing cost , high labor productivity.

VI.Our suggestions

In order to sever you better, please inform us in your email about your daily production capacity,

which kind of oil seed, covering space and other related data, we can design for you the most

cost efficient and suitable production line.your interest is our great success.

| Packaging Detail:container |

| Delivery Detail:10 days after getting your 30% deposit |