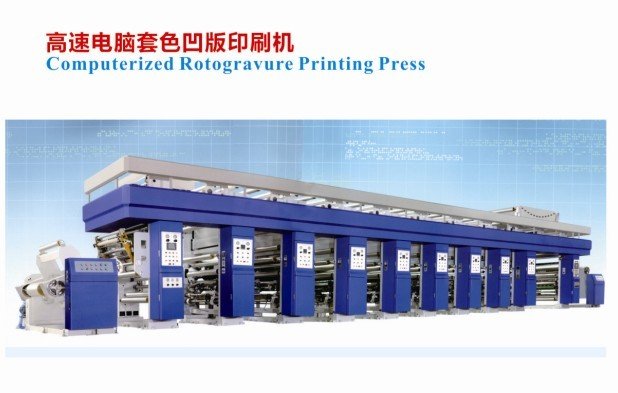

High-speed computer gravure printing production line

| Type:Rotogravure Printing Machine | Condition:New | Place of Origin:Shanghai China (Mainland) | Brand Name:UMA |

| Usage:Paper Printer | Automatic Grade:Automatic | Color & Page:Multicolor | Dimensions(L*W*H):width 850-1250mm |

| gravure printing machine:gravure printing line | Plate Type:Gravure |

This machine printing speed of 120 m / min, mechanical speed 130 m / min.

The main transmission mechanism: main drive motor with frequency converter control in Shenzhen Kymmene, drive each plate.

No axis Edition: loaded version with the cylinder, pulling mandrel for loading, horizontal adjustment by screw movement.

Features: change version to reduce the time, to ensure the version of concentricity, improve product quality.

Ink scraper: The blade can be adjusted up and down and angle, squeegee pressure double-cylinder, horizontal movement used motor rotational cam movement.

Features: extended version of the life.

Imprint lifting mechanism: double cylinder impression boost and solenoid valve from the lock position, on the cylinder leakage and cylinder shutdown protection under the swap.

Features: to ensure that the average pressure to ensure that color.

Chromatic manipulator: A computer-controlled synchronous motor ball screw by reducing the speed adjustment, automatic pre-register and chromatography.

Features: Moment of lubrication, high speed printing.

Collection, discharge institutions: The Double-income, put rack, paper wrapping and automatic feeding, use of magnetic powder discharge tension control, collection, discharge tension traction speed variable frequency vector control, receiving motor control using torque.Features: saving for high-volume printing materials, inks, solvents and energy.Then feed speed of 120 m / min up to about 20 meters then waste material; inks, solvents, energy saving about 10%, significantly reducing product costs.

Drying and cooling: centrifugal fan blowing smoke oven, electric oven quartz tube of hair found in the mouth of each heating, temperature control by the intelligent temperature controller, cooling with water-cooled roll back each group to ensure the film cooling.Features: saving electricity.

| Packaging Detail:The Goods are enveloped by polyethylene film and is packaged into wood pallet. |

| Delivery Detail:delivery in two months after contract |