High efficiency metal sheet rolling machine

High efficiency cold forming machine for roof and wall panel, 1. CE and ISO certificated, 2. best quality, lowest price - details see: https://www.machineto.com/high-efficiency-metal-sheet-rolling-machine-10086345

| Type:Tile Forming Machine | Tile Type:Steel | Use:Roof | Place of Origin:Hebei China (Mainland) |

| Brand Name:Haide | Model Number:trapezoid | Certification:CE and ISO:9001 | Color:As customer requirement |

| Shaft:70mm | Roller steps:13 | Main structure:350H steel | Control system:Fully automatic |

| Inverter:Lenze | PLC:panasonic | Screen:Color touch screen | Motor brand:famouse in China |

High efficiency metal sheet rolling machine

Our machine has passed CE and ISO certificated

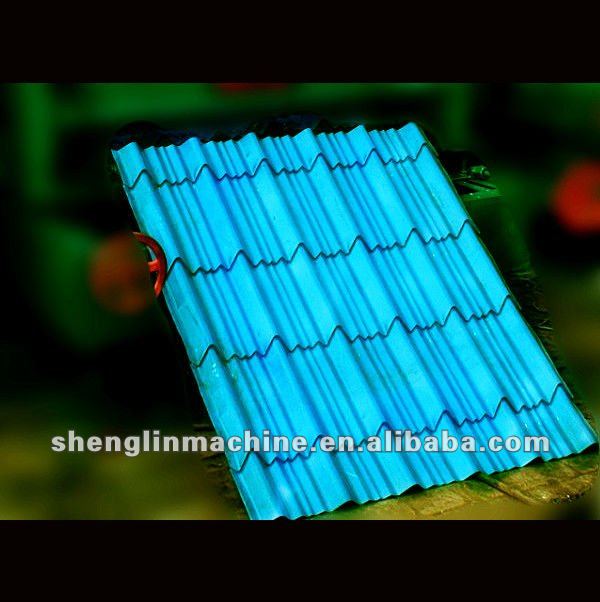

A profile with size

PS: the size is changable, please show us your desied size and then we design new machine specially for you

| Wave height | 31mm |

| Wave length | 201.75mm |

| Cover width | 808mm |

| Coil width | 1000mm |

| Thickness of material plate | 0.3-0.8mm |

B parameters

| No. | main parameter of metal sheet rolling machine | |

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | 1000mm |

| 3 | Rollers | 14rows |

| 4 | Dimensions | 8000mm*1550mm*1510mm |

| 5 | Power | 5.5+4kw |

| 6 | Thickness of the plate | 0.3-0.8mm |

| 7 | Productivity | 20-30m/min |

| 8 | Diameter of the roller | Φ80mm |

| 9 | Weight | About 2.5T |

| 10 | Voltage | 380V 50Hz 3phases |

| 11 | Material of the cutting plate | Cr12 |

| 12 | Hydraulic | 40# |

| 13 | Processing precision | Within 1.00mm |

| 14 | Control system | Panasonnic PLC control |

C flow chart of metal sheet rolling machine

D machine components of metal sheet rolling machine

1. decoiler(optional)

upgrade manual decoiler or 5 ton auto decoiler with car

2. Feeding device

3.hydraulic system

4 plc control box

5. forming rollers and transmission

6. whole machine

7. set off table (optional)

8 panel

9. panel usage sample

10.rollformerloading

CE and ISO certification

Contact:0086-15128722435

| Packaging Detail:1. Tighten to container with steel wire rope and welded machine with container by angel iron 2. Main forming machine and un-coiler is naked(If you need we can also packed with water-proof plastic) 3. PLC contral system and motor pump are packed in wooden box with water proof paper coverage |

| Delivery Detail:30 days after get deposit |