Condensate unit pump

| Place of Origin:Seoul South Korea | Brand Name:ILJINFLO | Model Number:HT & HMF Series |

COPYRIGHT © 2010 ILJINPUMPTECHNOLOGY CO.,LTD..

ILJINFLO ® IS A REGISTERED TRADEMARK OF ILJIN PUMP TECHNOLOGY CO.,LTD. PRINTED IN THE KOREA.

_____________________________________________________________________________________

SUGGESTED SPECIFICATIONS

ILJINFLO ® PUMPS

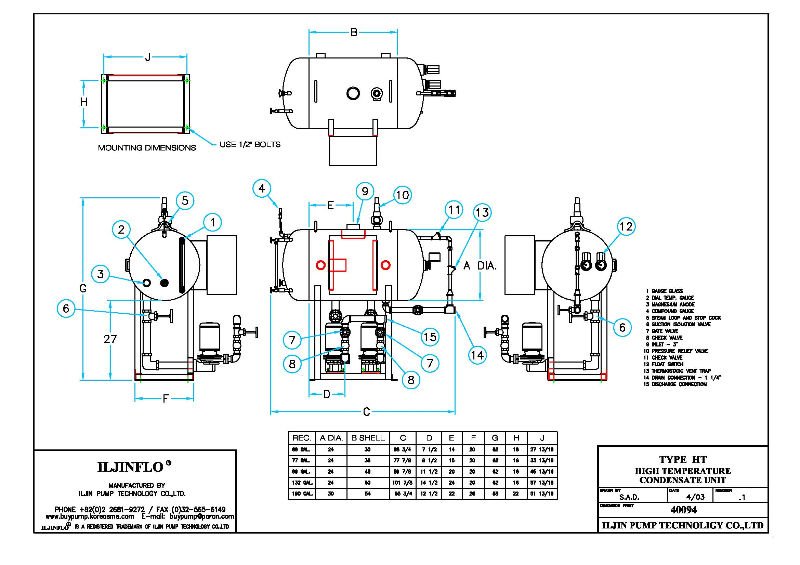

TYPE HT DUPLEX high temperature CONDENSATE return units for temperatures up to 250°F

CAPACITY SCHEDULE MUST BE COMPLETED.

Furnish and install according to drawings and manufacturers instructions the quantity of HT DUPLEX high temperature proportioning condensate return pump(s) as shown on the drawings. Each unit shall consist of (1) elevated steel receiver minimum3/16" thick (for operation up to 15 PSIG internal working pressure), (2) water pumps, (1) mechanical alternator, electrical controls and accessories.

The condensate receiver shall be minimum3/16" thick ASME Code stamped for 125 PSIG design pressure with1/16" corrosion allowance. The receiver head and shell thickness shall not be less than3/16" thick. The receiver shall be elevated 27" on a structural steel frame. The receiver shall be equipped with: (2) external float switch assemblies, (1) thermostatic air vent, top and bottom shut-off water level gauge with automatic shut-off if glass is broken, pressure relief valve set at 15 PSIG, compound gauge, electrolytic corrosion inhibitor (anode), dial thermometer, drain valve, (2) lifting eyes, (1) isolation valve between each pump and the receiver (in suction piping), (1) Isolation valve between receiver and pump plus a valve in each bleed line installed for maintenance, (1) pressure gauge for each pump discharge. The receiver size shall be as shown on the drawings.

The centrifugal water pumps shall be flange mounted on the suction pipe flange. The pumps shall be 2 stage close coupled vertical design. The first stage shall be an axial flow impeller discharging through a diffuser to the second stage. The second stage shall be a cast bronze impeller that is bronze fitted to the cast iron pump housing with a renewable bronze wearing ring. The mechanical seal shall be tungsten carbide rated for 300°F service. The entire pump assembly shall be permanently aligned and dynamically balanced to deliver its full rated capacity with 2 ft. of NPSH. The pump shall be driven by a vertical 3500 RPM industry standard motor available "off the shelf." The motor shall have a NEMA standard shaft. The horsepower and electrical characteristics shall be as shown on the drawings.

The pump manufacturer shall furnish, mount on the pump unit, NEMA MG1 control cabinet with hinged door, containing:

2 Combination magnetic starters (each having 3 overload relays) with circuit breakers and cover interlock for lock-out tag-out capability

2 Automatic-Off selector switches

2 Momentary contact Test push buttons

2 Pilot run lights

1 Numbered terminal strip

1 Removable control mounting plate

Each pump control circuit shall be completely independent of the other. The external float switch assemblies provide simultaneous operation under peak load conditions, and operate the second pump automatically, should the active pump or its control fail.

The unit shall have an external float switch assembly to turn on a high water alarm mounted in control panel with bell, light and silencing relay with dry contacts to access the building management system alarm.

A control circuit transformer for each circuit shall be provided when the motor voltage is three phase or code requires 115 volt controls. All factory installed wiring shall be numbered for easy identification and the numbers shall coincide with those shown on the wiring diagrams.

The unit shall have a single point power connection.

The entire pump package will be ISO9001/NAMA MG1. labeled when a control panel is furnished.

The manufacturer shall furnish a certified pump performance test. The pump manufacturer shall furnish complete elementary and connection wiring diagrams, piping diagrams, and installation and operation instructions.

Manufacturer shall be ILJINFLO® PUMPS,

Capacity Schedule (Required to complete suggested specifications).

E-mail :

Phone +82-(0)2-2681-9272

Mobil phone: 011-352-1648

TYPE HT-D CONDENSATE PUMPS SCHEDULE:

Capacity: __ _ LITTER/HR @ _____ BAR.G

_____ KW, __ _ RPM

Current: __ __ phase, 50 cycles, ___ _ volts, Motor Protection / Insulation _ /_ _

| Packaging Detail:Export wooden standard |

| Delivery Detail:within 6 weeks |