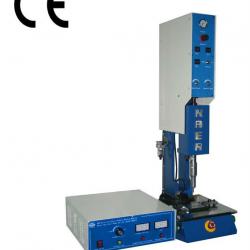

CE Certificate High Stability Ultrasonic Welding Machine

| Place of Origin:Shandong China (Mainland) | Brand Name:KAER | Model Number:KCH-1020 | Voltage:220V |

| Power:1000W | Frequency:20KHz | Welding Area:depend on mould size | Dimensions:350*480*1080mm |

| Weight:130kg | Usage:welding plastic | Certificate:ISO9001 and CE | welding head material:aluminium alloy,titanium alloy,stainless steel |

| Generator Size:410*470*170mm | Color:blue and white | Working Pressure:0.15-0.8MPa | Welding Time Control:0.01-9.99s |

| Dwell Time Control:0.01-9.99s | Route Journey:less than 130mm |

Economical Type Ultrasonic Welding Machine

Main Applys to

1. ABS,PC,PE,non-woven,acrylic material,etc.,

2. Some applications as below.

a)Electric products : telephones, MP3 sets, SD cards, earphones, flash discs, solar energy fittings

b)Medical products : dilators, tee for medicine fillings, liquid medicine filters

c)Packaging and clothing : valve bags, paper cups, fake-proof wine bottle caps, zippers

d)Stationery and toys : namecard holders,plastic toys

KCH-1020 ultrasonic welding machine have earned the certificate ofCE and ISO9001.

Feature of ultrasonic welding machine

1. Efficiency : the welding process is very fast ,welding time is only 0.01-9.99 second.

2.Strength : the weld joint has same strength as the base material).

3.Quality : finished product is airtight and watertight.

4. Cost : non bolt or glue, reduce labor and costs .

5. Appearance : The joints are repeatable, clean and precise.

Specification of ultrasonic welding machine KCH series

1. Aluminum alloy whole frame, high-rigidity;

2. AIRTAC pneumatic components durability;

3. Automatic and manual operating mode, convenient for adjusting;

4. Normal temperature-circulation self-cooled ultrasonic generator with original;

5. Constant power output circuit never overload for avoiding poor welding.

Device and Mould

1) 1set of mould include 1pc horn and 1pc tooling,

2) horn material :1) titanium alloy,2) alunimium alloy,3) stainless steel.

Photo

Our services

Before-sale service procedures: trial welding of samples → providing solutions

In order to save investment, shorten investment period and get the return from investment,

please submit the following documentations to us in advance:

A. Product drawings and/or three more pieces of product samples;

B. Materials used on the product;

C. Product welding requirements and acceptance method: 1) strength requirements; 2) tightness requirements; 3) appearance requirements; 4) other special requirements.

D. Production scale. Please indicate the maximum output per shift (8h).

E. Is there any assembling process before welding? Is it required for checking the samples one by one after welding?

We will offer you the best effective solution free of charge:

1. Perform trial welding on your samples free of charge.

2. Check the die drawing and confirm the optimum structure and size in conformity with the ultrasonic technology.

3. Recommend equipment to you according to the principle of optimum input-output ratio.

4. Design and produce the dedicated ultrasonic equipment or automatically assembling and welding production line according to your requirements.

In-sale service procedures: equipment installation and commissioning →training at the customer’s

place

1. Deliver the equipment according to the contracted schedule.

2. Installation and commissioning at your site;

3. Provide professional training on personnel responsible for operating, maintenance and management.

4. Provide technical guide to ensure that you can produce high-quality products at high-efficiency.

After-sale service procedures: lifetime equipment maintenance → regular customer visit

1. For simple faults, our technicians will guide the customer to solve it over telephone;

2. For complicated faults, we diagnose the fault situation beforehand and offer a quotation to you;

3. Arrive at the field of fault within the time specified in the contract.

4. Regularly visit customers to improve service quality constantly.

5. Offer lifetime service at a preferential price.

| Packaging Detail:non-fumigated plywood case |

| Delivery Detail:7 working days |