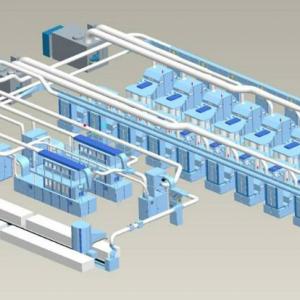

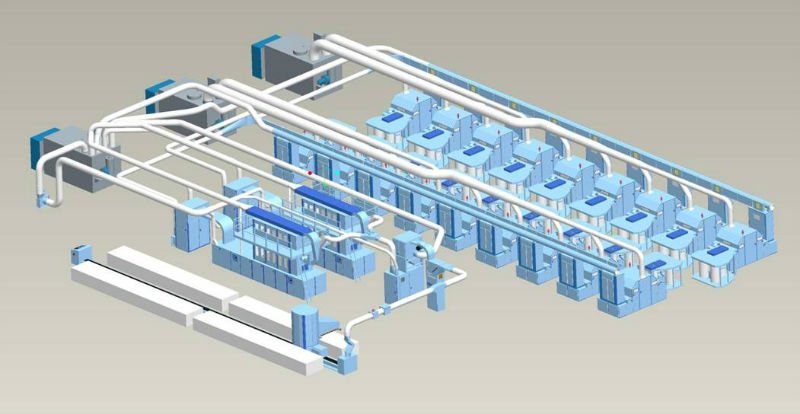

Blowroom-carding

In 1993, signing the textile transfer contract with Trutzschler GmbH Co., - details see: https://www.machineto.com/blowroom-carding-10276988

| Condition:Used | Place of Origin:Henan China (Mainland) | Brand Name:JINGWEI | Model Number:Blowroom-carding line |

In 1993, after signing the textile transfer contract with Trutzschler GmbH Co., it acquired the advanced know-how in design, manufacture, installation, adjustment and maintenance of the Blowing-Carding machines. During the 10 years co-operation period, it spent 5 million DEM for the textile technology documentation and know-how of more than 22 Blowing-Carding machines (including BDT019,BO,AFC,MM6,CVT3,DX,FBK533,DK760), and also imported more than 30 sets of specialized equipment and inspecting instrument. Besides, it has 300 person·time trained on production management, technology, marketing and after-sales service by Trutzschler GmbH Co..From 1993 to producing carding machie,2001 more than 500 sets,2006 more than 2000 sets.Until end of 2011, the production of carding machine above the 18000 sets.

Blowroom and cading machine main features:

1. According to the pipeline pressure changes, the whole system can realize continuous and stable feeding by using control cabinet and Continue Feeding device. We adopt import Continue Feeding device with PID control function; it can correct the feeding automatically and ensure blowroom 100%running. This device can meet the changes of blowroom and carding production automatically. When the system running normally, the pressure fluctuations is ± 20Pa can achieve true continuous feed. We can ensure stability of whole line production even carding machine only one can running.

2.Network control system (Optional)

(1)Various parameters display and modification in blowroom and carding machine.

(2)Indicating fault spot for blowroom machine and running condition for carding machine.

(3)Integral database.

(1)Various parameters display and modification in blowroom and carding machine.

(2)Indicating fault spot for blowroom machine and running condition for carding machine.

(3)Integral database.

CARDING MACHINE

1. Frame,cylinder,doffer and licker-in are all constructed of sheet metal welded with high precision,good rigid, light weight and good balance.

2. High efficient suction hood mechanism replaces traditional grids,web cleaner around the cylinder to improve sliver quality.

3.Key parts are manufactured through Machine Center and special machine with high precision to ensure tiny clearance and strong carding capacity. Radial jump of cylinder is less than 0.015mm.Cylinder dia.: 1290mm,doffer dia.: 700mm.

4.PLC,industrial touch screen control, feed in card and doffer are controlled by frequency converter,long-term and short-term mixed loop qutoleveller.

5.Adopted inclined tri-roll stripping mechanism with good effort of stripping and transferring.

6.Unidirectional feed technolog.Metal proof device at the end of feed roll.

1. Frame,cylinder,doffer and licker-in are all constructed of sheet metal welded with high precision,good rigid, light weight and good balance.

2. High efficient suction hood mechanism replaces traditional grids,web cleaner around the cylinder to improve sliver quality.

3.Key parts are manufactured through Machine Center and special machine with high precision to ensure tiny clearance and strong carding capacity. Radial jump of cylinder is less than 0.015mm.Cylinder dia.: 1290mm,doffer dia.: 700mm.

4.PLC,industrial touch screen control, feed in card and doffer are controlled by frequency converter,long-term and short-term mixed loop qutoleveller.

5.Adopted inclined tri-roll stripping mechanism with good effort of stripping and transferring.

6.Unidirectional feed technolog.Metal proof device at the end of feed roll.

| Packaging Detail:wooden case |

| Delivery Detail:60 DAYS |