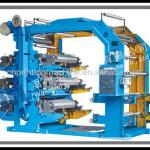

6 Colors Stack Flexographic Printing Machine(CH886)

| Type:Flexographic Printer | Condition:New | Plate Type:Letterpress | Place of Origin:Zhejiang China (Mainland) |

| Brand Name:changhong | Model Number:CH886 | Usage:Paper Printer | Automatic Grade:Automatic |

| Color & Page:Multicolor | Voltage:22/380V,3P | Gross Power:42KW | Dimensions(L*W*H):5.2m*2.4m*3.2m |

| Weight:6.5T | Certification:CE | Printing Speed:30-80m/min | Flexographic Printing Machine:Paper printing Machine |

| anilox roll:ceramic anilox roll | Ink runnnig way:with doctor blade | tension control:auto tension control | EPC:edge position controller |

The main features:

1. Take it easy, accurate color, long life

2. The use of motors, variable frequency speed control, saving electricity, running small fluctuations

3. Off printing roll automatic stop the ink-running motor, and up-printing roll automatic start running the ink

4. The use of special diagonal-tooth gear, print size is accurate,

5. There are two sets of heating devices, including central heating and constant temperature control system for packet control

6. Low-roller special steel processing, and special process, and plating thickness of 0.1mm protective layer of hard chromium

7 Alloy roll with hard oxidation, treating by dynamic balance, static balanced

8 With a cold wind bellows, and can effectively prevent produce with ink adhesion after printing

9. The Print produce are clear and good arrangement quality

10. Bearing: NSK, Japan brand, Germany ASNU aluminum alloy roll

Main Technical Parameter:

| Max. printing material width | 1050mm |

| Printing width | 960mm |

| Printing material | OPP:20~70μm,BOPP:18~60μm,PE:35~100μm, NY:20~50μm,PET:12~60μm,CPP:20~60μm, paper: 20~350g/m2 |

| Printing color | 6 color |

| Printing length | 7.5"~40"(190mm~1000mm)/7.5"~50"(190mm~1270mm) |

| Machanical speed | 90m/min |

| Printing speed | 30m-80m/min |

| Register precision | Longitude:±0.15mm Transverse:±0.15mm |

| Rewinder/Unwinder DIA | Φ1200mm |

| Printing plate lifting system | Automatic Hydraulic cylinder control printing roll up and down |

| EPC system: | Edge Position Controller 1 PC |

| Tension system | automatic tension control for unwind |

| Unwinding loading and rewinding unloading way | By air shaft , 2 pcs |

| Printing Pressure | mechanical adjust |

| Anilxo roll | ceramic anilox roller, one side doctor blade |

| Master motor | 3.7Kw TAIWAN BRAND |

| Drying way | Electrical heat drying |

| Drying power | 18 kw (it is special with double surface blowing ,wind cooling circulate, drying fast,also with high speed drying for fastness , with 2set |

| Blower | 1.1 Kw X 3pcs |

| Blower of nature wind | 1.5Kw x2pcs |

| Inking motor | 200W (Taiwan brand) |

| Master frequency converter | 3.7 kw (DELTA brand ) |

| Master power | 30Kw |

| Dimension(L×W×H) | 5.2 ×2.4× 3.2m |

| Packaging Detail:as required |

| Delivery Detail:60 days |